Having left school at 15½ years of age, Chris Boylan began his apprenticeship at Percy Main on 17th May 1954, and amazingly he can still remember the first engine that he worked on - a Class J27 0-6-0 No 65839. Whilst at Percy Main he spent a brief three month period at South Blyth in 1955, then a year later he moved to Gateshead in December 1956. After three years at Gateshead he moved to Darlington North Road Works in July 1959. Within three months he was back at Gateshead where he finished his apprenticeship aged 21 in December 1959.

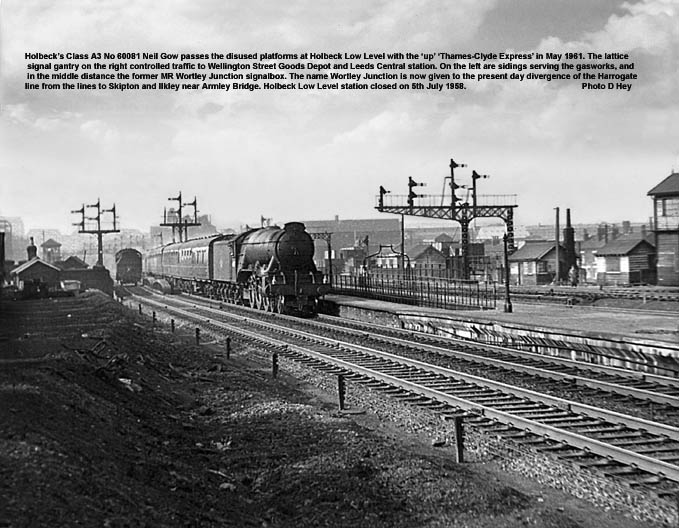

His first shed as fitter was Neville Hill, Leeds where he spent ten months before returning to Gateshead in October 1960. Chris spent 18 happy years at Gateshead before moving to Heaton HST depot aged 40 in February 1978; this was followed in July by a move to South Gosforth to see the DMUs out whilst local services were taken over by the METRO.

Two years later it was back to Heaton again to concentrate on the old-type DMUs and to see in the new Class142/143s and Trans Pennine sets. Finally, after 43 years service, 58 year-old Chris called it a day in July 1997, his last job being a Trans Pennine Unit Class 158 747. This is Chris's story....

When David first put forward the idea of a page on the Internet I was dubious at first, but then he suggested that like Freddy Wagstaff before me I'd soon get the hang of it - and he was right…I couldn't stop scribbling!

So here I go with life's ups and downs as a BR Fitter working on the old steam workhorse, beginning with my time at Percy Main. Life in a running shed could be rich and varied, though it all depended on the weather, of course - summer or winter, the old steam horse never stopped. At small depots like Percy Main or Blyth an easy shift might consist of making sanding gear operable, adjusting brakes or tightening glands up.

At 52E (Percy Main) if a loco came in with a broken main spring, she would be banished to the 'New Shed' for attention by the men on standing work before returning to traffic. Yet even the smallest jobs, such as removing a regulator gland stuffing box and extracting the old packing, then scraping the stuffing box face joints, making a new joint, refitting it to the boiler and packing the gland, was always a job worth doing well. Seeing the steam-tight joints on the locomotive working next day gave me a great sense of satisfaction; the same thing can be said for grinding a regulator valve under the supervision of one of my mentors Ned Abbott. When you were in the fitting shop or the machine shop, you would find a locomotive under the Shear Legs being lifted for attention to axleboxes that had run hot and demanded a job done well.

Perhaps the staff working conditions could have been better…but they weren't - they were abysmal! For one thing, there was no hot running water to get washed at the end of a shift, and being the apprentice I had to carry two buckets to the nearest engine and drain off hot water for the mess room, where a bucket of sand was available to help with the removal of grime. Worse still, many shed roofs were in a perilous condition, leading to them being removed for safety reasons and temporary covers (more like permanent ones) were fitted in an attempt to shelter staff from the weather….some hope! Conditions at Percy Main steam shed were the least to say prehistoric…established in the 1850s the old shed roof was deteriorating rapidly. After I had gone to Gateshead the roof was removed completely. A part reroofing job was done on  the East Road so that locomotives could be prepared under cover. You could squeeze a couple of J27s underneath. Still I loved the job right to the very end…more is said at the bottom of the page

the East Road so that locomotives could be prepared under cover. You could squeeze a couple of J27s underneath. Still I loved the job right to the very end…more is said at the bottom of the page (Above-Right)

(Above-Right)

(Below) This photo of George Wombwell attending to Class J27 65819 at South Blyth shed (52F). The loco is probably receiving attention to some loose nuts on her slipper block on the RH piston (piston to con rod) connection, just one of the little intricacies required in maintaining a loco.

During my career as a Fitter, I worked with a lot of fellow workers at various depots over 43 years, many of whom belonged to what I call the last 'job-for-life generation'. A retired driver friend of mine, who had a two year start over me (he began on the railway in 1952) summed it up whilst guzzling my whisky one night - 'You know what, Chris,' he said - 'You and I, and others of our age group…had the best of the system.'

He was absolutely right…most of the men I worked with were first rate and only the odd one or two were not so easy to get on with. When I started at Percy Main in May 1954, I was lucky to meet some great blokes, including the examining fitter, Henzel Adamson, who taught me a lot about the lesser known, but just as important minor jobs in engineering maintenance, such as making tail trimmings and gauging needle trimmings in eccentric straps. Poor old Henzel was crippled with arthritis and at times I helped him out by moving dead engines with a pinch bar on certain jobs he was doing.

Then there was Micky Gillinder (the Fat Lad) who had a great sense of humour and kept us going with a  stream of jokes. He also imparted a lot of knowledge which I was glad of during my early apprenticeship days. His mate Albert - nicknamed 'The Pad' - was another very funny character in his own way. Another fitter called George White was quiet and studious, and also helped me to learn new skills. His mate Peter was a good ambulance man but never bothered with competitions. Ned Abbot was quite a novelty to work with; he was deaf, and on more than one occasion, whenever someone was playing hell with him, would slip his hand inside his overalls to turn off his hearing aid then stare blankly at the person in total silence. His mate, Norman, was a slow but steady man, whose main interest was the horses - he loved a bet. Like a lot of fellow workers, fifteen minutes or so of the morning was spent studying racing form whether it was at Catterick or Wetherby. All in all, the lads at Percy Main were a good lot to work with.

stream of jokes. He also imparted a lot of knowledge which I was glad of during my early apprenticeship days. His mate Albert - nicknamed 'The Pad' - was another very funny character in his own way. Another fitter called George White was quiet and studious, and also helped me to learn new skills. His mate Peter was a good ambulance man but never bothered with competitions. Ned Abbot was quite a novelty to work with; he was deaf, and on more than one occasion, whenever someone was playing hell with him, would slip his hand inside his overalls to turn off his hearing aid then stare blankly at the person in total silence. His mate, Norman, was a slow but steady man, whose main interest was the horses - he loved a bet. Like a lot of fellow workers, fifteen minutes or so of the morning was spent studying racing form whether it was at Catterick or Wetherby. All in all, the lads at Percy Main were a good lot to work with.

At Percy Main there were twenty two J27's allocated to the depot, sixteen of which were allocated to regular crews. The rest were the 'common users' with no regular crews, and were used to provide cover for engines under repair and routine maintenance, or when visiting either Gateshead Works or Darlington North Road Works for overhaul. I'll never forget the sight and sound of the Q6s and J27s as they worked their hearts out climbing the bank from Seghill to Benton, especially at night when they produced the most glorious pyrotechnic displays. Mind you, if it was a frosty night, the old electric trains did not do too badly either, their collector shoes arcing off the third rail made quite a spectacle!

I will never forget my first experience of heavy work as an apprentice at Percy Main (52E). It involved Class J27 No 5825 which left Whitehill Point sidings with a load of 21 ton hoppers for Ashington Colliery, but had only got as far as TIC No 6 Box (Tyne Improvement Commission Signal Box) when there was a loud bang from underneath. The driver shut off steam and went to see what had happened; his examination elicited the fact that she had failed with the RHS crankshaft broken and that meant only one thing…Tool Vans.

I was allowed to go with the vans to see how the failure was dealt with. First the side rods were removed, then wedges were placed in front of the driving wheels and our loco (sister J27 No 5796) drew No 5825 forward so the driving wheels rose up on the wedges enabling us to pack the underside of both axleboxes prior to removing the mainsprings and placing a large tie bar across the wheels to hold them in position. Then our loco gently nudged the casualty backwards so the driving wheels floated free. The train was then re-marshalled and we set off back to the shed with our lame duck in tow. When we got back to the shed 5825 was turned on the table and placed in the fitting shop head first under the shear legs ready for lifting.

Next morning the tender was parted from the engine and disposed of outside the shop. The valve gear was dismantled and the eccentric strap sheaves renewed and a steel bogie rolled in under the axle and chained down. The axlebox stays were then removed and the loco lifted allowing the axle to be rolled out and the right hand wheel to fall onto the fitting shop floor. A special wheel-carrying wagon arrived overnight from Darlington Works, the wheels and axleboxes were loaded up and dispatched back to  Darlington for repair. We also sent the sizes of the axlebox guides (horn guides) by railway post. One month later we got the wheels back with the axlebox sizes as we had sent and the new bearings bedded in. All we had to do now was refit the eccentric sheaves, re-assemble the valve gear and lower the engine back onto its wheels. We then fitted the new springs, put the side rods back and recoupled the tender. The next day she went back in service and we got a few more miles out of her.

Darlington for repair. We also sent the sizes of the axlebox guides (horn guides) by railway post. One month later we got the wheels back with the axlebox sizes as we had sent and the new bearings bedded in. All we had to do now was refit the eccentric sheaves, re-assemble the valve gear and lower the engine back onto its wheels. We then fitted the new springs, put the side rods back and recoupled the tender. The next day she went back in service and we got a few more miles out of her.

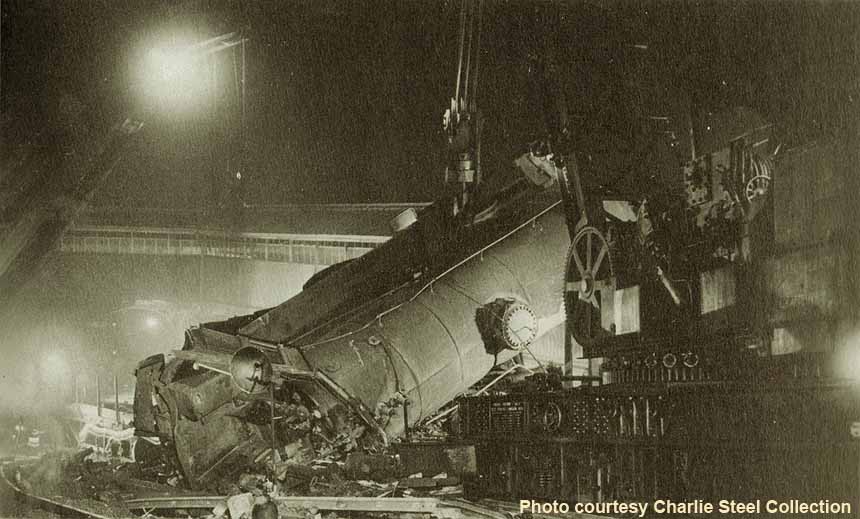

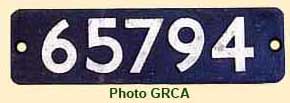

Staying with the Class J27 - one Saturday morning in April 1955, No 5794 was running tender first from Heaton to Tynemouth via Backworth. As she passed under Front Street Road Bridge in Monkseaton the tender suddenly lurched to the right, derailed then turned over and dragged 5794 over with her. The engine landed on the platform upside down and the driver was trapped by the reversing lever and unable to move - how he was released and to what extent he and his fireman's injuries were I do not recollect. Ambulances were there quickly to render what aid they could until the tool vans arrived, one from Gateshead the other from Tweedmouth. (Gateshead from the south end and Tweedmouth worked from the North end). The accident happened at about 09-30am, and it took all day Saturday - including through the night and all day Sunday - until the early hours of Monday morning before the damage was cleared. The gangs worked so hard that the track and the third-rail were soon re-laid and the first electric train of the day passed through to pick up its passengers at Monkseaton. I have it in mind that the tender was loaded up onto a bogie wagon and taken away, whereas No 5794 was dumped in a siding and covered over with tarpaulins to hide her from view. She stood there for a week until she was spirited away in the early hours to Darlington Works for a complete overhaul and rebuild. One month or so later she was back in action looking smart in her new paint. Incidentally the cause of the derailment was the middle tender axle broke.

After the incident the management deemed it necessary to examine all tenders of similar types of engine classes, hence B16s, Q6s, Q7s, J25s-26s and 27s were called into North Road Works for their tender axles to be ultrasonically tested. This produced some unexpected results. It was found that a lot of the axles were in a dangerous condition which had management's bums twitching! The suspect axles were all changed while those that were adjudged to be OK were returned to traffic and allowed to run. After some months all this ceased and management heaved a collective sigh of relief.

When I was an apprentice at Percy Main Micky Gillander was a good friend to me. The last I heard he was living somewhere in the Shiremoor area. At South Blyth we learned how to maintain engines without any machinery…all we had was a hand-operated drill! I suspect many trips were made to the colliery workshop over the road for help. I recall 5808 ran a RHD box hot and she was jacked up on a bogie, had the bearing renewed and the engine lowered back on to the rails. Guess what…she ran hot again two days later and was sent to Percy Main for lifting. Some days after that, a G5 came knocking on the fitting shop door for attention. She had one bogie axlebox hot and a bogie mainspring broken. However, as one set of shear legs was tied up with a Neville Hill J39, the G5 was turned and put bunker first under the other shearlegs; the bogie was then removed and shunted outside the workshop (gingerly I might add) with the bunker on a platelayer's bogie. We did this because 5825 was waiting inside with a broken crankshaft---Although I was at South Blyth for only three months, I recall my weekly duties with the G5s.The ones with Push/Pull had to be dosed with castor oil in the regulator diaphragm to keep them supple and the Westinghouse ones had to have the compressor governing cap nuts removed and all the lumps and bumps from coal and prods from scar shovels to get them going again. Of the South Blyth staff, I remember Isaac Dixon, driver - Ray  Wood, passed man and Wilf Kneebone, office clerk. Among the Maintenance Staff were Alfie Edwards, chargeman - Fitters Ned Sparks, Geordie Wombwell, Jack Mavin and Davy Pawson. The boilersmith was Bill Shepard (ex-Starbeck) and his brickarch man Geordie Stephenson, who used to chew tobacco (filthy habit). Although I never got to the North Shed I knew some of the maintenance staff: Sid Collins, Bill Copeland, Fred Churchill and Danny Barker spring to mind.

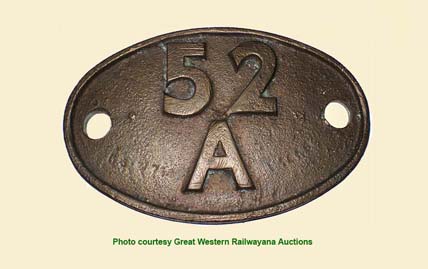

Wood, passed man and Wilf Kneebone, office clerk. Among the Maintenance Staff were Alfie Edwards, chargeman - Fitters Ned Sparks, Geordie Wombwell, Jack Mavin and Davy Pawson. The boilersmith was Bill Shepard (ex-Starbeck) and his brickarch man Geordie Stephenson, who used to chew tobacco (filthy habit). Although I never got to the North Shed I knew some of the maintenance staff: Sid Collins, Bill Copeland, Fred Churchill and Danny Barker spring to mind. (Above Left-Right) Brass Shedplate 52A Gateshead until October 1965 for steam, then May 1988 for diesel. This ex NER shed used brass codes on its allocation of diesel locos, mainly Class 46 'Peaks' and the Class 55 'Deltics'. Chris adds, 'Gateshead used cast iron plates generally. They were attached to all locos from Class 55s to humble 03 shunters. (Right) Shedplate 51A Darlington (1948 to March 1966) This ex-NER shed housed 112 locos in 1950, but by 1959 this had dwindled to 70. During its BR life the shed was home to no fewer than 16 different A3s and 12 different B1 Antelopes. In 1965 its solitary A1 'Kenilworth' was often found on ECML standby duty. A dozen 0-6-0 diesel shunters also carried this code. Chris comments - '60124 Kenilworth was usually 52A but transfers of A3s and A1s between Gateshead

(Above Left-Right) Brass Shedplate 52A Gateshead until October 1965 for steam, then May 1988 for diesel. This ex NER shed used brass codes on its allocation of diesel locos, mainly Class 46 'Peaks' and the Class 55 'Deltics'. Chris adds, 'Gateshead used cast iron plates generally. They were attached to all locos from Class 55s to humble 03 shunters. (Right) Shedplate 51A Darlington (1948 to March 1966) This ex-NER shed housed 112 locos in 1950, but by 1959 this had dwindled to 70. During its BR life the shed was home to no fewer than 16 different A3s and 12 different B1 Antelopes. In 1965 its solitary A1 'Kenilworth' was often found on ECML standby duty. A dozen 0-6-0 diesel shunters also carried this code. Chris comments - '60124 Kenilworth was usually 52A but transfers of A3s and A1s between Gateshead  and Darlington were quite`common to ensure a good loco for pilot duties at Darlngton. An example 60058 transferred to Darlington and 60075 returned to Gateshead. I sometimes worked in Darlington Shed with a works fitter looking after ex-works locos being run in prior to being returned to their depot

and Darlington were quite`common to ensure a good loco for pilot duties at Darlngton. An example 60058 transferred to Darlington and 60075 returned to Gateshead. I sometimes worked in Darlington Shed with a works fitter looking after ex-works locos being run in prior to being returned to their depot

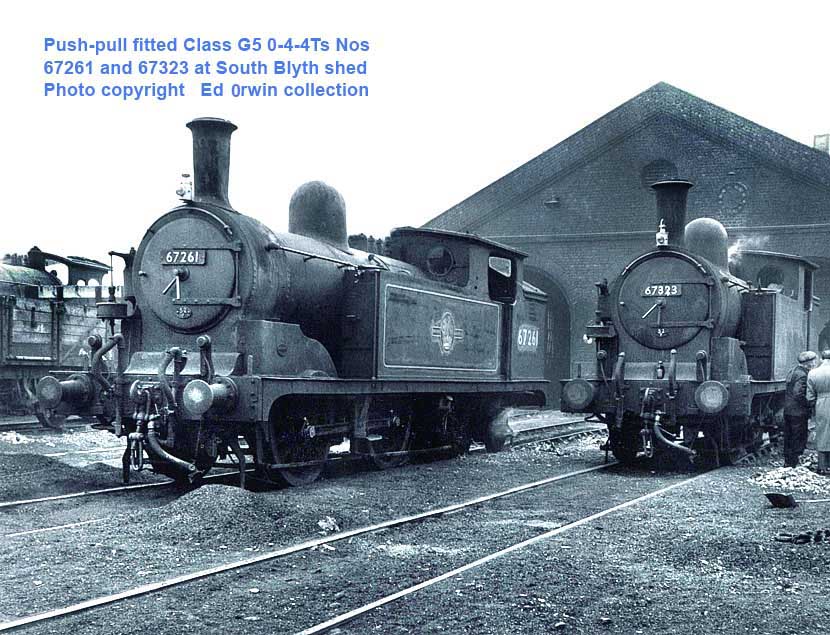

(Below-Inset Left) This photo of G5s at South Blyth reminds me of the time I had to attend to No 7323 at West Sleekburn; she had failed with the r/h con rod breaking in front of the big end strap - what a mess it made of the firebox! Another G5 7261 was usually well turned out, though not in this shot mind - and 7340 (extended tanks) came a close second. I remember 7340's driver talking to her in Blyth station. To save any misunderstanding about engine numbers - I, in the same way as other railwaymen did not give each loco its full number. For example 60137 is 137, 60868 is 868, 67261 is 7261, 68309 is 8309 and so on....this stems from Edward Thompson's renumbering scheme of 1943 which was altered by BR in 1948 when 60,000 was added to the existing fleet numbers. (Inset) Whilst on the subject of G5 locos, I recently rediscovered this 10ins by 15ins bell code plate that I had acquired years ago from a long forgotten Class G5 0-4-4 tank loco bound for the scrap yard. I cleaned it up and mounted it on a circular plate for display, but for some reason it found its way into the garden shed where it remained out of sight for donkey's years. I had forgotten all about it…I wonder how much it is worth today?

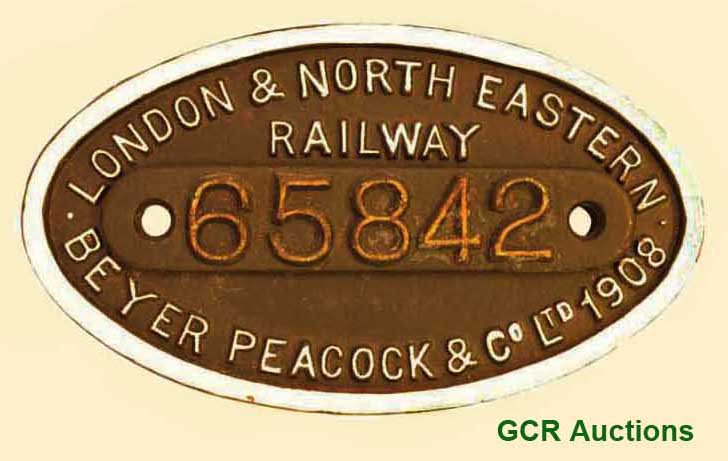

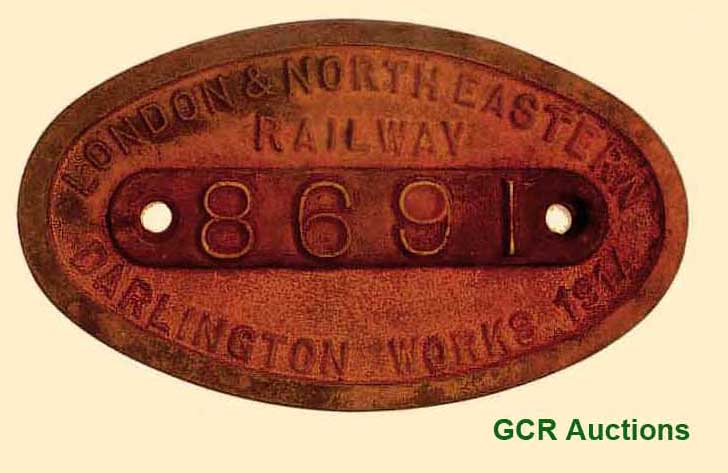

(Above) 65033 at Darlington North Road on 28th July 1963. Class J21 was a lightweight version of the J27 but with larger wheels. Not all were fitted with air-vacuum brakes. In their early days they worked Newcastle to Leeds goods via Harrogate and Ripon. 65033 ended her days at South Blyth for working the Rothbury Goods. The last batch of J27s numbered 65860 to 65894 (the Raven Version) were equipped with Schmidt piston valves which were absolute b-----ds to remove and the same problem occurred with the Q6s. The piston valve heads back and front were the same size and with the valves having one broad ring on each valve head presented problems in getting the valves out when doing a valves & pistons exam. These locos were not fitted with anti-carbonisers as were the Gresleys; consequently the buildup of carbon was horrific. The B16/1s and Q7s were the same. What a pity Sir Vincent did not listen to his son in law, none other thanEdward Thompson. For all their drawbacks, though, the Thompson and Peppercorn locos had anti-carbonisers and differential valve heads (back head smaller than the front) and four valve rings on each head. When refitting these valves the secret of success was plenty of oil and they flew in. It's amazing what a good de-coke could do. Taking the valves out was very onerous and the gear we was used would have done credit to Heath Robinson, master inventor of the weirdest contraptions.  (Left) Great Central Railwayana Auctions recently sold a cast iron works plate measuring 9"x 5" for Class J27 No 65842, a Percy Main J27 and one time a Selby loco. The Percy Main drivers were Tommy Adams and Jack Emmerson. This repainted locomotive worksplate shows the lettering: London & North Eastern Railway, Beyer Peacock & Co Ltd 1908, along with with a brass renumbering strip (65842) in the centre under which the locomotive's original number 1204 is visible. Originally a North Eastern Railway Class P3, later LNER J27 Class 0-6-0, numbered NER/LNER No 1204, later renumbered 5842 in 1946 and finally BR 65842 in 1948. The loco was allocated to Heaton in January 1948 before moving to Percy Main and North Blyth from where it was withdrawn in January 1967 and sold for scrap to J Willoughby at Choppington.

(Left) Great Central Railwayana Auctions recently sold a cast iron works plate measuring 9"x 5" for Class J27 No 65842, a Percy Main J27 and one time a Selby loco. The Percy Main drivers were Tommy Adams and Jack Emmerson. This repainted locomotive worksplate shows the lettering: London & North Eastern Railway, Beyer Peacock & Co Ltd 1908, along with with a brass renumbering strip (65842) in the centre under which the locomotive's original number 1204 is visible. Originally a North Eastern Railway Class P3, later LNER J27 Class 0-6-0, numbered NER/LNER No 1204, later renumbered 5842 in 1946 and finally BR 65842 in 1948. The loco was allocated to Heaton in January 1948 before moving to Percy Main and North Blyth from where it was withdrawn in January 1967 and sold for scrap to J Willoughby at Choppington.

(Above-Below) This atmospheric photo of Gateshead's old 45 ton steam crane recovering an overturned Class J27 after a major incident at Monkseaton Station was kindly provided by my friend Charlie Steel. The nocturnal shot shows the Gateshead 45 ton crane being prepared to lift Class J27 No 65794 back onto its feet. The derailment happened on Saturday 13th October I956 at 09.10. The engine Class J27 0-6-0 65794 was hauling 22 plate wagons bound for the ship yards at Wallsend, running tender first and as the engine passed under Front Street Road bridge, the middle tender axle broke and the tender overturned dragging the engine with it. The driver of the loco was trapped in the cab; the two firemen (one was learning the route) escaped without injury and the guard suffered shock. They were taken by ambulance to Tynemouth Infirmary for treatment where the driver was detained with a broken leg. Breakdown Trains were summoned from Gateshead and Tweedmouth (Berwick) to deal with the incident. Trains to Blyth were suspended. A service was resumed with electric trains on Monday night and normal service on Tuesday. Official enquiries revealed that no fault was attached to the train crew. In the background you can just see the jib of Tweedmouth's 45 ton crane helping out in clearing the debris. In this shot (below) the errant 65794 was hidden beneath a tarpaulin cover in a siding at the station for a brief spell before being removed to Darlington North Road Works, stripped down and rebuilt. It was quick work and she was back in service within a month; she was seen shunting at Monkseaton about six weeks after the accident.

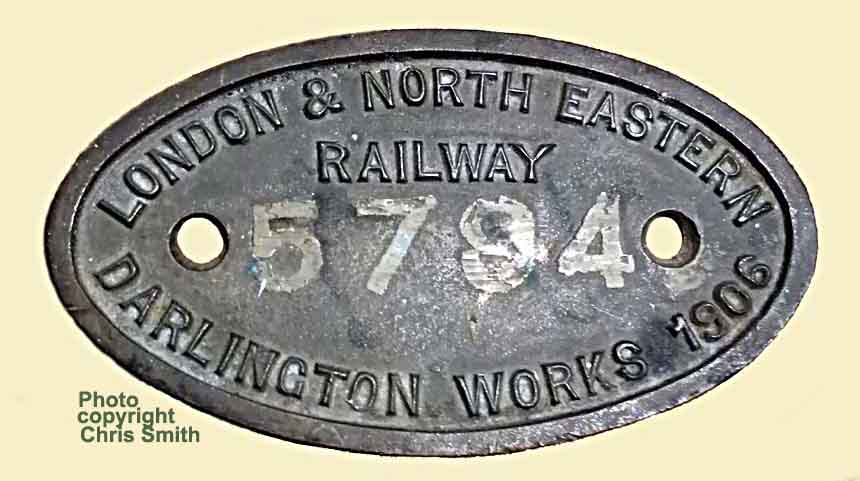

(Below) Chris's reference to the incident involving Class J27 65794 at Monkseaton (above) prompts Chris Smith of Somerset to drop a line. He writes - 'I have a worksplate for this particular Class J27 so it's useful to read the information in Chris Boylan's piece. Also it may at last explain why the numbers on my worksplate (photo below) were filed down. The earlier inset photo of the worksplate for 65842 (above) shows the BR number on a piece of metal overlaid on the original plate. Maybe there was a similar overlay made for 65794 thus requiring the filing…'

At Percy Main, our twenty two J27s were washed out every fourteen days, two engines per day. It was arranged for the locos to be on the depot by 2pm so the fire could be dropped before they were placed in the 'new shed' and steam tested and then left to cool down in readiness for the boiler washers 6am start the next day. Outstanding exam items were attended to - big ends, slipper blocks plus any booked repairs and whatever else the examining fitter might find required attention. Mostly the fires were back in by 4pm, though that depended on the boilersmith finding nothing wrong with the stays or a brick arch. If the boiler was due for what was known as DBI (District Boilers Inspection) the inspector would come from Darlington and the gauge class cocks were reamed out, the pressure gauge tested on the test rig and the safety valve seals inspected. If the seal wires were not looking good the valves were renewed. We had four spare engines, which covered Wash Outs, Heavy Repairs, and engines in Darlington Works plus one on the yard  pilot where we could keep an eye on her. One engine comes to mind, 5837. She had a Lockyer regulator which was so finely balanced that it could be opened and closed with just one finger. It came to pass that she was called in to Darlington for general overhaul and came back with a different boiler. Her driver was none too suited and complained to the Shed Master that the 'bulls horn' regulator was too heavy to work. It was explained to him that she had to take whatever boiler was available.

pilot where we could keep an eye on her. One engine comes to mind, 5837. She had a Lockyer regulator which was so finely balanced that it could be opened and closed with just one finger. It came to pass that she was called in to Darlington for general overhaul and came back with a different boiler. Her driver was none too suited and complained to the Shed Master that the 'bulls horn' regulator was too heavy to work. It was explained to him that she had to take whatever boiler was available.

When I returned to Percy Main from South Blyth shed the first of the English Electric DE shunters arrived along with three fitters from Heaton. I caught up with them later at Gateshead when Percy Main closed in 1965 and the diesel locos and men came to Gateshead.

Established in 1831 by the Newcastle and Darlington Railway, the locomotive works at Newcastle moved to the Greensfield site at Gateshead in 1854 and became the manufacturing headquarters of the NER. In 1909 loco construction was transferred to Darlington North Road Works and the Greensfield site closed in 1932 but reopened in 1939 after the outbreak of WW2 to relieve the strain on Darlington.

When I was at Percy Main, part of my duties was to get spare parts for locos from the works at Gateshead (on occasions North Road could not supply them quick enough) and Gateshead was basically the main stores for the sheds in the Newcastle and Sunderland areas. It made a refreshing change to see the various types of loco that did not work into Percy Main such as G5 tanks, Q6s and others. They even started to overhaul the Ivatt 2MTs from the Scottish Region. I believe 46464 was the first one and a damned fine job was done on her.

There was a constant stream of wagons carrying loco boilers from Gateshead to Stooperdale Boilershop at Darlington. All in all, a Q6 or J27 could be turned round in just over three weeks excluding the running-in turns. All the overhaul work on locos and tenders was done in No1 shop, whereas the valves & piston exams were carried out on the A1s, A2s, A3s and A4s in No 2 shop; this work was done on two roads. The remaining 3 roads were used for lifting J39s and Q6s etc, with two 45 ton overhead cranes provided the lifting gear. When the cranes were erected, a test load was carried out hoisting a Class A4 from one end of the shop to the other and back again. The funny thing was that the fitting and repairs in No 2 shop were done by shed fitters, whereas No1 shop was regarded as a different department with the work carried out by CME fitters. There was the usual compliment of heavy machinery, the oldest of which was the wheel lathe built by Noble & Lunds of Gateshead in 1882 and lasted until 1965 - No 2 shop remained open until 1965 for heavy repairs to Q6s and J27s.

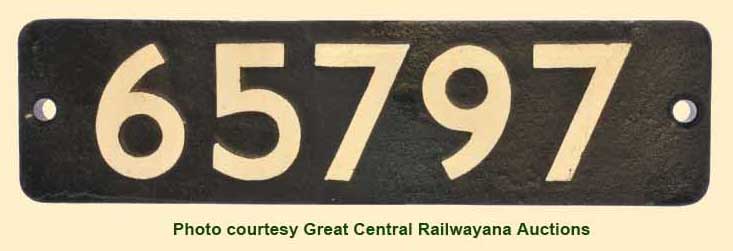

(Above) A forlorn-looking Class J27 No 65852 awaits its fate in Darlington Scrap Yard on 26th January 1964. This venerable lady was born in August 1908 at Beyer Peacock and died in December 1963…a loyal, hard working servant to the end. Fitted with slide valves she was my introduction to the first valves & pistons exam as a 17 year-old apprentice with Fitter Jack Scott. The Staff and locos at Percy Main were known as 'What Fets' - a Tyneside greeting, which roughly translated into English means 'What's your fettle, I trust you're well! (Left) A smokebox number plate from Class J27 No 65794 went under the hammer at a Great Central Railwayana Auction on 17th January 2009. This is the loco that overturned in Monkseaton Station in 1955 and later rebuilt at North Road Works Darlington, which I mention on the second page. Built at Darlington in October 1906, its NER/LNER number then was 1189, later becoming 5794 in 1946 and 65794 in BR days when it was allocated to Percy Main but spent most of its time at North Blyth from where it was withdrawn in June 1965.

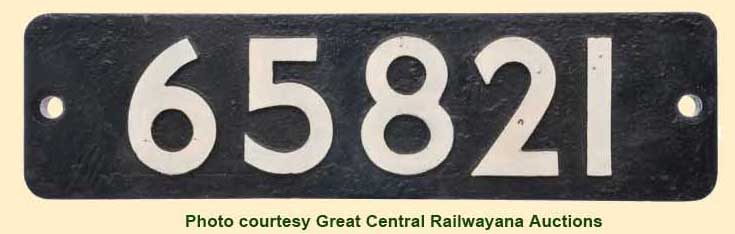

(Left) A smokebox number plate from Class J27 No 65794 went under the hammer at a Great Central Railwayana Auction on 17th January 2009. This is the loco that overturned in Monkseaton Station in 1955 and later rebuilt at North Road Works Darlington, which I mention on the second page. Built at Darlington in October 1906, its NER/LNER number then was 1189, later becoming 5794 in 1946 and 65794 in BR days when it was allocated to Percy Main but spent most of its time at North Blyth from where it was withdrawn in June 1965.  It spent five months in store at North Blyth before being scrapped at Ellis Metals, Swalwell, Derwenthaugh in the November. (Right) A smokebox number plate for Class J27 65821 went under the hammer for £540 at a Great central Railwayana Auction on 17th July 2011. A Percy Main stalwart, the loco was the prized possession of Drivers Ted Nash and Gordon Heslop for many years. Originally numbered NER/LNER 1034, the loco was renumbered 5821 in 1946, later finishing its days as BR 65821 at South Blyth from where it was withdrawn in February 1966 and cut up at Hughes Bolckows.

It spent five months in store at North Blyth before being scrapped at Ellis Metals, Swalwell, Derwenthaugh in the November. (Right) A smokebox number plate for Class J27 65821 went under the hammer for £540 at a Great central Railwayana Auction on 17th July 2011. A Percy Main stalwart, the loco was the prized possession of Drivers Ted Nash and Gordon Heslop for many years. Originally numbered NER/LNER 1034, the loco was renumbered 5821 in 1946, later finishing its days as BR 65821 at South Blyth from where it was withdrawn in February 1966 and cut up at Hughes Bolckows.

(Above-Below) This David Salmon shot of the electric trains certainly bought back some memories for me. They were dumped at Heaton steam depot which had just closed prior to being dispatched to Messrs Bolckow at Blyth. This is why for safety reasons all the collector shoes and their suspension beams were removed and thrown into the passenger saloons. E29164 and its trailer were the stars of the fleet. They were the only set that had roller bearings in their axle boxes. If this set was standing on its own, you could release the brakes and two behemoths could move the set by throwing their weight against the buffer beam. No mean task I assure you! (Below) This Pullman Car has being laid aside for repairs and awaits the attention of staff or is ready to be put back into a train. Top left of the photo you can see the roof of the coal stage at Heaton.

A funny story comes to mind concerning 5812. Her driver lived in Knotts Flats at the south end of Tynemouth Station. If he was finishing on his last job passing Tynemouth he would blow a prearranged code on the whistle and his wife would start the dinner. After some time, the other Percy Main drivers started the same caper and this led to utter domestic confusion.

(Above-Below) Darlington Works was responsible for building the J39s - all except for a batch of twenty eight built by Beyer Peacock and Co between 1926 and 1937. The design was very similar to their sires, the J38s - the first LNER standard design for a 0-6-0 goods locomotive. The J39 first appeared in 1926 (with larger wheels) and a total of 289 were built over fifteen years. (Below) This particular ex-wks J39 would be the cleanest anyone would see a J39. The loco became 4796 - later No 64796 in BR days after nationalisation. Cowlairs Works assumed responsibility for the North Eastern and Scottish Region J39s. David tells me that this is a super-wide image. Seemingly you have to click once, then a second time on the photo to see the full size…

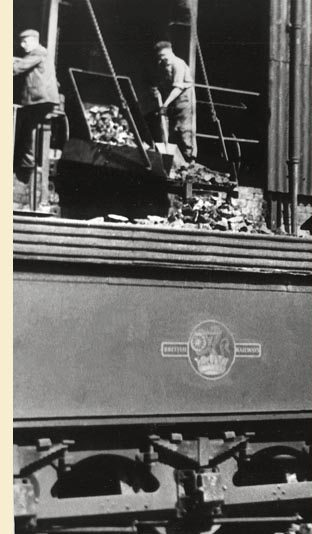

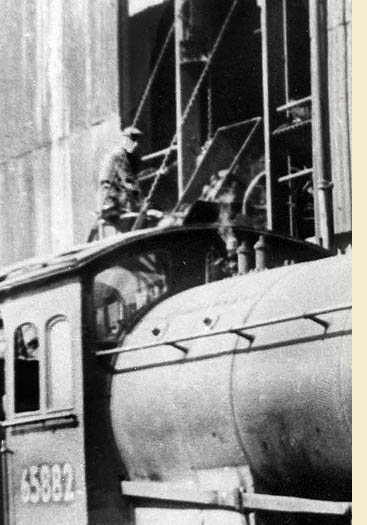

(Above-Below) Here we see one of the begrimed J39 workhorses at Borough Gardens Shed. During the mid-Fifties, the shed code of Tyneside's main depot at Gateshead was 54A; followed by sub-sheds at Durham (DUR); 54B Tyne Dock (TDK); Borough Gardens 54C (BOR) and 54D Consett (CON). When the 'Gardens' closed, its staff came to Gateshead, and ex-Gardens fitters Marky Bradshaw and Chad Fairley are two of the fitters I worked with that spring to mind. Withdrawal of the J39 started in 1959, with all 289 gone by the end of 1962. This rapid withdrawal of the class was because of their higher than average maintenance costs, due mainly to their hot axlebox problem which was never solved. (Below) Darlington Works in 1964. The Weigh House is where locos were weighed after overhaul. At least there was a six foot deep pit to work in - not like Gateshead where you had to crawl under on the flat! Although I was only at Darlington Works for the last six months of my apprenticeship in 1959, I remember my time there like yesterday. I was in the Light Repair Shop working with a damned good fitter called Matty Hudson, who hated being reminded that he was a dead-ringer for that well known Hollywood actor, Randolph Scott. I recall watching a set of main frames for a 350hp EE shunter being put through a rolling machine to true them up by a chap called Fred Catterick, whose brother was none other than Harry Catterick, then manager of Everton FC. You never knew who you'd meet on the job! One could watch the 350hp shunters being built in the Light Repair Shop, right from the frames coming out of the rolling shop to the complete loco leaving the shop for trials; it would take on average about three weeks. Mind you there were only two shifts - days and nights - and contesting for the space were the Type 2 Sulzers - later Class 24/25s - in various stages of construction. In this 1964 view of the yard a BR Standard Class 4MT loco is being prepared for transfer to Darlington Bank Top Shed before dispatch to its home depot. The Works kept two fitters at Bank Top for minor adjustments. The line of redundant WD tenders is to provide a pool of spare parts from withdrawn surplus serviceable locos. Click here to visit Roy Lambeth's 'Rail Cameraman' page

Before I went to North Road Works I recall an incident involving Class A3 No 60083 Sir Hugo which came to grief with a broken piston at Bridge House Junction just south of Durham. We were sitting in the mess room at Gateshead when the Charge Fitter came in and told my fitter and myself - 'No 83 has failed at Bridge House!'

The only thing known about the incident was that the left hand piston had broken, and so using our judgement we got our gear together and launched the lifeboat - sister A3 No 78 Night Hawk - and the rescue mission was underway. On arrival we found that the train had been removed and sent on its way south leaving the loco stranded; No 83's the piston had broken clean off from the cross head leaving the taper part stuck in the cross head. We secured the piston (making sure 83 was in middle gear - neutral) before coupling up No 78 to tow its sister back to Gateshead. During the post mortem it was found that 83 had just come off a heavy Valves & Pistons exam at its home depot. Repairs were affected by parking 83 in a road in the shed next to the buffer stops - she was well and truly wedged and adorned with NOT TO BE MOVED notices. After the cylinder head was removed, the piston was taken out, and the crosshead and con rod sent to Doncaster for repairs. About one month later 83 was back in action.... maintaining an Iron Horse was certainly not easy!

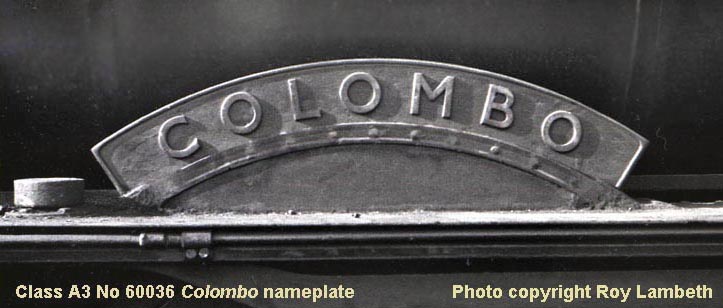

Following hard on No 83's heels was an incident involving another A3 No 36 Columbo. Every driver's fear was 'dropping a plug'. This was a safety device made up of two hollow brass plugs with the core filled with lead - the idea being that if the water level dropped to a dangerous level, the lead would melt instantly and extinguish the fire. This fusible plug was screwed into the firebox roof beneath the water space. If the boiler was rated at 250 lbs per square inch…well, I'll leave the rest to your imagination....

These plugs were changed every boiler washout. Anyway, No 36 Columbo had pulled up in Durham station on an 'up' train and while her crew stretched their legs on the platform for a few seconds the plugs suddenly blew with a God-almighty roar and put the fire out. The crew was literally shaking. When an incident like this occurred the loco was taken back to the depot for repairs, which entailed removing the safety valves and fitting blanks over the mountings. This was followed by removal of the regulator and blanking the main steam pipe off, then removing the boiler water gauge and blanking off the portways. The test procedure began by filling the boiler to the top through a special connection and using a pump to pressurize the boiler to double the pressure - plus 10 lbs. All steam pipe joints had to be watertight! What might be steam-tight at 220Ibs must be made water tight before the test could proceed. In this case 36's boiler had to withstand a water pressure of 440 lbs to the square inch. If she passed out (she did) the procedure was then reversed. The water gauge portways were reamed out and new gauge glass fittings and glasses replaced. The driver and fireman stated at the enquiry that when the train had stopped at Durham the glasses had indicated the boiler was half full which was okay.

Seemingly, the glasses had been blown through by opening both drain valves on each side of the boiler for a few seconds to clear the passages before leaving Newcastle. This was carried out in accordance with the Rules and Regulations, which stipulated that the glasses were to be blown through once per shift. This was done by opening the drain cock on the bottom of both gauge glass fittings (one fitting on each side of the boiler) for a few seconds to let the boiler pressure blow the water through a waste pipe to the track below. Oddly enough, with the exception of the GWR, all the railway companies (including British Railways) designed their boilers to be fitted with two gauge glass fittings - one on both sides of the boiler, but for reasons best known to themselves, the GWR only put one fitting on the fireman's side. I believe the Board of Trade was not wild with delight about this arrangement.

(Above-Below) A general view inside the main erecting shop. In the foreground is a V2 undergoing a general overhaul. In the extreme background is an A4. Next to the V2 (cheers from me again!) is what looks suspiciously like a Stanier 8F - Crewe and Derby must have been full! LNER Pacifics were generally dealt with by Doncaster. I remember a B1 No 1034 (minus its bogie) arriving in the light repair shop for collision damage repairs. What a mess she was in! The front buffer beam was all but torn off and the main frames badly bent. The repair necessitated removal of the boiler from the frames and removal of the cylinders. It was calculated how far back the frames would have to be cut. The frames were then cut and new pieces welded on at both sides - and, if I recall rightly, frame stiffeners were attached on the insides. The cylinders were then refitted and lined up, the bogie and new buffer beam fitted and the nightshift refitted the boiler. A few days later, after all the work had been completed, a hale and hearty B1 left for its home depot at Thornaby. About a week later another B1 appeared for a light intermediate repair. The District Boiler Inspector had not been happy with the state of the boiler water gauge passages and had 'red-ticketed' the boiler, which meant that it could not to be put into steam. After discussion it was decided that the water gauge passages would have to be reamed out internally which necessitated removal of the regulator and myself crawling along the inside over the tubes with a very long reamer (a tool used to enlarge or shape holes). Lights were hung in the cab and I also had a torch. I could see the lights from the cab over the top of the firebox; the reamer was put in the ports and all of them given a good reaming out. All new gauge cocks and glasses were fitted before I managed to crawl back along the tubes and out again at the steam dome. Other repairs were completed by staff on both the dayshift and nightshift, and after various tests had been carried out, a much happier B1 left for its home depot. (Below) This photo of Class A8 Pacific Tank (known up here as Teddy Bears) No.69889 and Class 24 5099 was taken at Darlington North Road Works on 24th May 1960

(Below) Roy Lambeth writes: 'Thunderbird' duty 1964 steam style. In the event of a loco failure on the ECML, Gresley Class A3 60036 Columbo is standing by Darlington Shed turntable in 1964. The loco was built at Doncaster Plant (Works No 1791) in July 1934 originally numbered LNER No 2501. Withdrawn from traffic on 23 November 1964 the loco was scrapped at Drapers Hull in April 1965.

Staying with the A3s, I recall a problem with the exhaust steam injectors on No 60 'The Tetrarch' (named after the Winner of the 1913 Doncaster Champagne Stakes) which paid a visit to Doncaster Works for her General Overhaul. A little over a month later she re-appeared at Gateshead all spick and span, and would have done credit to either an Olympus or Leica camera - all sparkling new paint etc - but there was something wrong with her! Now before I explain what we found, I ought to first give a brief outline of what a steam injector's function in life is to a loco. On main line locos there were two water injectors that injected water into the locos boiler under high pressure. The L.H.S was worked by live steam only whereas the R.H.S could be worked by either live steam or exhaust steam, which was operated by an automatic changeover valve. Therefore if the engine was running with steam on and the exhaust injector working, as the driver shut the regulator the changeover valve would automatically work and the injector would continue its work uninterrupted on live steam. However, when No 60 returned from Doncaster it was found that while the exhaust steam injector worked on live steam it didn't on exhaust steam. So Stan and I changed the injector, but still the fault persisted. We stripped down the new injector then rebuilt it but still had no joy! Whilst mulling over the problem, Stan said - 'What is it we've had to do with each injector?'

I thought for a moment, then said - 'We've had to use the changeover cap nut off the original injector…the cap nut on the new one's missing…'

'Exactly!' he said, and with that we dived under the nearest loco and pinched its cap nut. Guess what? No.60's injector worked perfectly. We then removed the new cap nut and measured the depth of the internal recess and found it was deeper than the original. At this juncture, John, our Turner, took the cap nut to his lathe and deepened the recess and both cap nuts were replaced on the original locos. After that, No 60 passed her test on both live and exhaust steam, but how she managed to pass Quality Control at Doncaster, God alone knows.

(Above-Below) Judging by the setting of the points at the rear of the tender, V2 806 is coming 'off shed' at Darlington Bank Top on 16th July 1951. To the left of the photo is the now closed Darlington Power Station, which was later dismantled. To the right is where the new DMU depot was built, but that too was closed and dismantled. It came to pass that one of the Kings Cross V2s (damn-fine engines) paid a return visit to North Road; the loco was still under guarantee following a recent general overhaul and The Cross was complaining about a 'knock' on her right hand side - like most railwaymen, I refer to Kings Cross as 'The Cross', and before I forget, the V2 was No 871. We took her for a run up to Newton Aycliffe on the Bishop Auckland branch and the fault was diagnosed to be the rh-driving axle box knocking slightly. Back at North Road, the axlebox wedges were reset and the RHS con rod had its big end bush re-metalled. She was re-weighed in the weigh house and pronounced in top-notch condition. She was sent to Darlington Shed, and the next day took a parcels train to Newcastle via Bishop Auckland. I'm happy to say that she passed with flying colours and returned to her home depot.

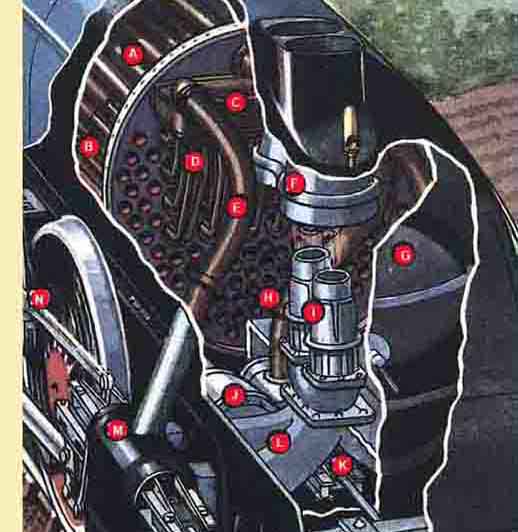

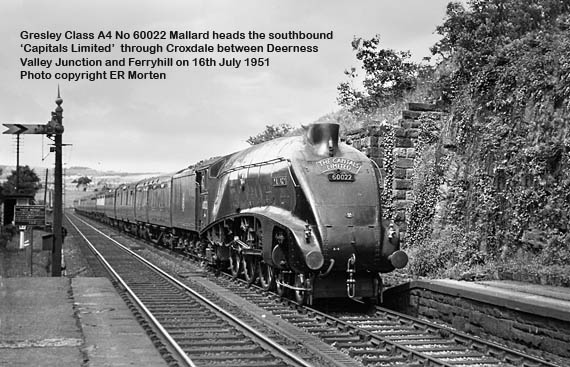

(Below) All railwaymen had their likes and dislikes between the various types of locos. One of my favourites was the Class V2 mixed traffic loco - one of Sir Nigel's masterpieces. The V2 was capable of matching the performance of a 'Pacific' any time, especially if it was equipped with the same exhaust system as its illustrious cousin 'Mallard', but this modification came a bit late for the V2. The general census of opinion among footplate staff was that they wanted more V2s like this, but only 12 were modified - it was said that one of these locos actually hit 100mph! From the maintenance staffs' point of view, there was little to moan about the V2. To dismantle the MBE (middle big end) it was necessary to remove a short portion of the vacuum train pipe which made the task a bit easier. You had a little more space under them than a 'Pacific' and the middle cylinder cover was a doddle compared to the Class A3 or A4. The work necessitated removal of a section of footplate under the smokebox door and then placing a piece of wood packing 24" long, 18" wide and 1" thick under the cylinder and over the frame stiffener. This allowed you to sit legs astride it and pull the cover onto the wood for support prior to lifting it clear with a block and tackle aided by your mate. Removing the middle piston valve presented no problem. The snag came when putting them back again! After the ring grooves had been cleaned and new rings fitted and the valve chambers de-coked, you had to be careful. It was a two man job, with one bloke 'stuck up a height' (an expression we used when working in a confined space under a locomotive, having climbed up amongst the valve gear etc) whilst the second man moved the valve as necessary. The biggest hurdle was a support girder under the smoke box which allowed you little space, but after you had done a couple of these jobs, it became a lot easier, though you did not rush them. The main reason the V2 was condemned to an early grave was due to their monoblock cylinder casting. For years Darlington had tried to get Doncaster to re-design the casting into three separate castings, which meant that if one cylinder was damaged it required only the renewal of that one cylinder, not all three. Doncaster did eventually relent and a few were modified. I hope my scribbled notes help people realise what went into maintaining the 'iron horse' and you don't think I'm boring the "c--p" out of anyone!

(Above) 60847 of 50A - one of Gresley's masterpieces; the double Blast Pipe ones were quite capable of 100mph; often used deputising for a Pacific - Keith Long's photo was taken at York (50A) on 17th April 1965. I remember a problem with sister V2 No 812 being dispatched from Heaton (52B) to Gateshead for her Valves & Pistons exam. Stripping her apart went well until it came to parting the middle piston and crosshead. It was solid and we could not get the crosshead key to move it. Everyone had ago but no one succeeded. Eventually after lengthy discussion a drastic decision was reached; Bob our gaffer said take the three motion bars down and turn the piston round until the narrow end of the key is facing the left-hand side of the loco. This was done and a heavy bar put through the spokes of the leading driving wheels and then called on the services of a really heavy hammer…but still no joy. Tony the boilersmith turned up with the oxy-acetylene cutters and burnt the end of the key off. Then it was necessary to grind the rags off and mark the key off for drilling. This was accomplished by using a heavy compressed air drill and jig. It also necessitated numerous sharpening of drills. When we had got three-quarters of the way through, Ted said - 'Right, let's give that hammer another go.' Rather unexpectedly the key shot out like a bullet. On examining the key way, we saw that the piston had been forced further into the crosshead creating a small shoulder. The piston and crosshead were dispatched to Darlington for reconditioning and when we got them back we finished off and 812 was put back into traffic. The three motion bars on Gresley, Thompson, and Peppercorn locos were rather awkward to handle especially the ones attached to the middle cylinder (due sharp edges) therefore personal safety was the order of the day. We watched ourselves with 812. After we finished, Teddy Gladstone came out with another of his sayings 'Nothing succeeds like success…'

(Below)The locos I detested working on were the un-rebuilt Raven Class B16 /1 and the Q7 heavy freight loco (NER Class S3 and T3). They were handsome looking locos but Raven persisted with cramming everything in between the frames on these two three-cylinder beasts - all driving off one axle. It would seem that Raven adhered to the dictum that his locos must look pleasing to the eye and to hell with the maintenance staff! His Class Z Atlantics and the Class 4-6-2 (LNER C7 & A2) were the same but they were gone before I started. The last one I hated was the Midland Class 4F 0-6-0. I did not like the vacuum brake system (neither did a lot of drivers). The LNER/BR system was much superior...or perhaps the dislike of the 4F was simply a case of the NER men not being familiar with Midland-LMS ideas? In this photo, Class B16/1 No 61446 heads through Monkton Moor on the now-closed Harrogate-Ripon line in the 1950s. The fact that it is hauling Stanier LMS type stock makes me think that the train is a relief from Newcastle to Liverpool (engine change at Leeds) probably a bank holiday working. If you could imagine a pair of carrier wheels under the cab of 1416/466 you would be looking at Sir Vincent Raven's ill-fated Pacific turned out in 1922.

If ever a loco was designed to thrive on neglect...the Q6 was it! The locos were constantly being thrashed flat-out for indefinite periods and still asking for more - a tribute to its designer Sir Vincent Raven and the Darlington North Road Works. Mister Potter assures me that they were the only engines he knew where the boiler would steam against both injectors. Ask him about his pet Q6 3408? However, the one thing I did not like about them was the brass liners in the eccentric straps. When dismantling them one was always conscious that they could take your fingers off if you did not watch it, especially if the wheels were out of the loco the block and tackle crane was there. I recollect a fitter having a finger end sliced off when he dropped the brass liner. You had the same problem with the Thompson and Peppercorn A1s and A2s...their straps were a three man job, at least. One night at Neville Hill I was topping up 3449's reverser oil cylinder when it blew back in my face. My idiot mate had fallen asleep on the driver's side and his arm dropped down and knocked the steam valve open. Did I doubt his parenthood? I absolutely hated the J39s - 'Do-it-yourself hernia kits' I called them! Gresley did not appear to consider the fitters who had to keep them in running order. I cringed at the thought of having to do a valves & pistons exam. On refitting the con rods you had to line up eight holes on each side, the two slipper blocks, the con rod itself and the main frame. The pistons had three rings to a head which made it slightly harder than an A4 (two rings). The J39 might have been a strong, capable loco but they were very costly to upkeep, which is why all 285 locos were scrapped in less than two years. The same goes for the J39s' next door neighbour - and one might say their sires - the J38s, which were just as awkward. Both were barred from places where a more useful J27 could go. But let's not forget everybody's favourite (including me) that old warhorse the Q6...

(Above) I cried seeing this magnificent beast in its death throes. No doubt the spirit of Sir Vincent Raven felt a little downhearted also. I believe its last depot was Blaydon or Tyne Dock. The demolition of condemned locomotives at North Road was a very public operation, as the activity was carried out close to North Road station, just visible in the background.

Roy Lambeth writes: 'I spent many afternoons at Darlington North Road Scrap Yard, first travelling by train from Durham to Darlington Bank Top, and then to North Road Station on a DMU service either to Penrith, Middleton-in-Teesdale or Crook. On arrival at North Road, it was a mad rush over the wooden footbridge and out through the ticket office to see if there had been any changes in the scrap yard since my last visit. The scrap yard was visible from the station steps, and I recall seeing the two loco cabs from Sentinel Class Y1s, which were used as staff bait cabins for many years. In those days cheeking your elders was something that no boy ever tired of, and I was no exception! I found that if I cheeked the men in the scrap  yard, they would throw things at me, including lumps of brass! As a result, I am now the proud owner of six brass BR number plates (especially cast to bolt over the old LNER Works Plates) and all due to being cheeky!'

yard, they would throw things at me, including lumps of brass! As a result, I am now the proud owner of six brass BR number plates (especially cast to bolt over the old LNER Works Plates) and all due to being cheeky!'

Photographer Keith Long adds: '63385 in North Road Scrapyard Darlington on 26January 1964. Even though a lot of work has been done on her, the cab and running plate have all gone, yet she still carries her number plate and 52C Blaydon shedplate. Photo details: Negative scan. The camera was an Ensign Selfix 820, using Ilford HP3 Black & White 120 Roll Film developed in home bathroom darkroom...' Click here to visit Keith's excellent Flickr Photostream.

I am fascinated by the railwayana items that appear on the auction websites. They certainly strir a few memories...here we have a North Eastern Railway Class Q6 0-8-0 locomotive chimney measuring 28" diameter at the base with a 16" flue below, 24" diameter cap with 17" chimney hole. The length including the bottom flue is 38". The chimney went under the hammer at a Sheffield Railwayana Auction in March 2012, however the auctioneers didn't know the identity of the loco, but it was in good ex-loco condition and sold for £240. Chris adds - The Class Q6 was a freight loco loved by both footplate and maintenance staff alike. How many times did this chimney climb the spiritual homes of the Q6 on the Consett and Seaton Banks? All I know is that the sound effects were once heard, never forgotten..'

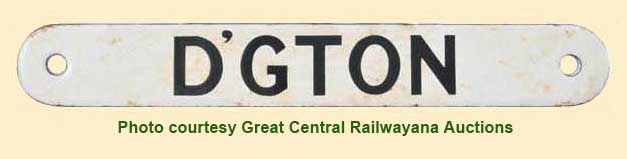

(Below) Another enamel shedplate, this time for D'GTON (Darlington), went under the hammer at Great Central Railwayana Auction in 2011. These plates were affixed inside the cab roofs from December 1938. This ex-NER shed had around 100 locos during the 1930s.

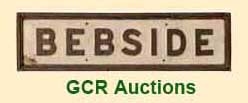

(Left) A North Eastern Railway signal box nameboard, Bebside, from the Blyth and Tyne route between Morpeth and Newcastle, went under the hammer at a Great Central Railwayana Action in April 2012. The board was in original condition consisting of cast letters on wood measuring 42"x11". The station closed in 1964. (Below Right) The same auction also handled a single line key token - Scotsgap-Wansbeck - from the Reedsmouth to Morpeth route which closed to passenger traffic in

(Left) A North Eastern Railway signal box nameboard, Bebside, from the Blyth and Tyne route between Morpeth and Newcastle, went under the hammer at a Great Central Railwayana Action in April 2012. The board was in original condition consisting of cast letters on wood measuring 42"x11". The station closed in 1964. (Below Right) The same auction also handled a single line key token - Scotsgap-Wansbeck - from the Reedsmouth to Morpeth route which closed to passenger traffic in  1952 and freight in 1956.

1952 and freight in 1956.

(Below) The Class B1 was the LNER equivalent of the LMS Black 5. It was designed by Edward Thompson under the shadow of WW2 and was a 'go anywhere-do anything' machine. Their Achilles Heel was a tendency for rough riding and 1022 was no exception. The loco was used mainly on the Newcastle to Carlisle runs, but her rough riding led to drivers refusing to take her off the depot at Gateshead. Things got so bad it was decided to take her out of traffic and investigate her thoroughly. First the bogie was removed and after measurements were taken it was found that the pivot pin was slightly worn. This was made true and a new pivot pin bush made by the turner...a great turner was our John, especially using micrometers. The bogie was then refitted and the loco moved forward to accommodate the trailing wheels on the 'drops'. The second step involved Dennis, Bob and me (the apprentice) in removing the trailing axle box springs. We were then given instructions to replace them with springs used on Pacific Type locos. After the weight was adjusted accordingly, 1022 became a loco that drivers fought over to take out on a run anywhere. Unfortunately General HQ at York got to hear about the changeover of springs and we were told to replace the standard B1 springs again. Result - yes, you've guessed it - a rough riding B1 again! It's rather coincidental, but a few months later she was called in to Doncaster for a General Overhaul. A driver friend of mine (now retired) once told me that the only way to fire a B1 on the Newcastle-Carlisle run was during a station stop at Hexham or Haltwhistle, where you could build the rear end of the fire box up and let the rough riding shake the fire forward! Here Gateshead's B1 No 1019 heads past Forthurn Box just outside Barnard Castle with an up train in the late 1950s.

(Above-Below) On retirement of Edward Thompson in 1946, Arthur Peppercorn became CME of the LNER. He had 18 months in office before the railways were nationalised, during which time 49 Peppercorn A1s were built. In true LNER tradition, several members of the class appeared with names of racehorses and birds, but five engines carried names of the constituent railway companies which had gone to make up the LNER, including 147 North Eastern, seen here heading a Kings Cross train at York. The full complement of 49 engines was not named until the early 1950s. This was my favourite A1 and one of Gateshead's stalwarts - No 147 North Eastern, while her two close stablemates Nos 126 Sir Vincent Raven and 127 Wilson Worsdell were stationed at nearby Heaton 52B. (Below) A fine study by Keth Long of North Eastern in the roundhouse at Leeds Neville Hill on 17th February 1963. Built at Darlington in April 1949 she was withdrawn on 28th August 1964 and scrapped at Drapers Hull in November 1964 - an interesting experiment involving 147 is described below.

When a Class A1 was using its vacuum ejector to create the vacuum for the train brake, the noise at the chimney top was deafening and train passengers would be hard pressed to hear the station announcer giving out information over the loud speakers. After some years, a rather ingenious device was produced to silence these monsters. It consisted of a multi-tube silencer about 18"diameter by about 26-27" long with a 6" deep chamber and pipe connections at both ends. Doncaster Works supplied the blueprint for the job and six A1s were selected for the trials - two came from 'The Cross', two from Gateshead and two from Haymarket. The Gateshead two were 137 and 147. The modification entailed cleaning out the smokebox - yeuk! - before removal of the ejector exhaust pipe. The pipe was then cut and the silencer welded into the pipe...and the result? It actually worked! Nos 137 and 147 were tried out in Newcastle Central (with the steam valves wide open) and all that was heard was a deafening silence! You could hear the train announcements clearly. Similar results came from 'The Cross' and Edinburgh. But I dare you to guess the outcome of the trials? For some reason no further action was taken and the scheme was dropped. Can you figure that one out? The A1s were noisy for the rest of their lives. The plan had been to silence all the other Pacific types but in the event the trial was all for nothing.

(Above) One Monday morning Ray Walker the charge man in the light repair shop at North Road sent for Matty Hudson, Harry Wade and myself. Our mission was to travel to the old National Railway Museum at York, where the curator wanted some jobs doing on some of the exhibits - one of the engines was none other than 'Gladstone', a product of the London Brighton & South Coast Railway's Brighton Works. The side rods were removed and the condition of the bushes checked, though why the curator wanted to know this escapes me now. I took the opportunity to have a look around her and found that she was equipped with a speedometer consisting of a gauge glass enclosed in a graduated brass tube connected to a wheel-driven pump. The faster the loco went the higher up the tube the water level rose. On recollection this fitting had a faint likeness to the hydrostatic oil tank of a Class 47 diesel. The name of the driver, William S Love of Brighton, was painted on a sign inside the cab. We did a few jobs on several other locos, and after three days returned to North Road - all in all a very enjoyable few days. This photo shows Gladstone in residence at the Queen Street Museum on 3rd August 1965.

(Above-Below) Class A4 No 60034 Lord Faringdon heads the northbound Tees-Tyne Pullman through Hitchen in 1960. (Below) No 60007 Sir Nigel Gresley and Class A3 No 60061 Pretty Polly were photographed by Keith Long at Doncaster Works on 20th May 1962. In the background is a glimpse of things to come - Brush Type 2 (Class 31) and EE Co Type 4 (Class 40) awaiting acceptance trials before their introduction to BR traffic.

DONCASTER TRAINING SCHOOL

Over the years several trips were made to the Training School at Doncaster for instruction on the various types of equipment associated with the different types of new diesel locomotives entering traffic during the transition from steam. One of these trips gave me my first sighting of the Class 23 loco (Baby Deltic) which sadly had a very dismal career and a short one at that!

An instructor whom I met on several occasions was Ralph…his surname escapes me now, but I do recall him telling us that he was on the construction gang that built the last steam engine at Doncaster. Ralph could best be described as an entertaining character; he was the possessor of a voice like a foghorn that would rival Tynemouth Pier Light House! One day he was taking us through the Davies & Metcalfe brake system on a Class 47, explaining what happened when a driver commenced to apply the brake - when, without any warning, our ears were assailed with a sudden and most unexpected outburst - 'What the hell do you think about the council house rents in Doncaster?'

Everyone's jaw dropped wide open and for the next twenty minutes we got the shortcomings of Doncaster Council concluding with another eruption - 'The b-----s should never have done away with the Trolley Buses!'

It transpired that he was a staunch supporter of them and loved a trip north to see the Newcastle Trolleys. His Achilles Heel was later exposed when the subject turned to cars; a Ford man through and through, he was extolling the virtues of Dagenham. I disagreed with him saying my three choices were Volvo, Vauxhall and Riley...oh dear, you could have knocked me down with a feather - with a roar that sounded like Vesuvius, Etna, Stromboli, Mount St Helens and Krakatau had erupting altogether in the class room, he roared that anyone who disliked Fords should be castrated!

After his pyrotechnic outburst was over we carried on with the lesson just as before, and all in all Ralph was a good instructor and we hopefully gave a good account of ourselves. What I had picked up on the air brakes on the G5s at Blyth and the D20s at Gateshead certainly did help out with the air brakes/vacuum brakes on the diesel by remembering which valve did what and what its equivalent was on a dual braked diesels.

FUSIBLE PLUGS

I speak here of two retired friends and myself exchanging waspish tales about our respective railway careers, including a bizarre story about fusible plugs, though whether it is true or not I will leave others to judge. My friends were recounting the old days at Tyne Dock shed which provided locos for the celebrated iron ore trains that ran from Tyne Dock to Consett Iron Works with gradients as steep as 1 in 35 to 1 in 50 over 23 miles. The sight and sound of two heavy freight locos (one pulling and one pushing) as they worked their guts out with a load of 450 tons on the 1 in 40 climb through Beamish was not to be forgotten…you never saw a fat fireman on these jobs! The intensity of operation was such that if a ship was unloading at the iron ore quay, trains were running every two hours. Over the years these trains were handled by Q7 and O1s locos, and finally the all-conquering 9F 2-10-0. However, due to the volume of traffic you could not keep a loco standing idle for too long, therefore if a plug was seen to be leaking…not, I hasten to add, due to the lead core melting - the problem was dealt with by the boilersmith, who first moved the fire to one side and then put some wet sacks over the fire hole. Then, after emptying a bucket of water over himself, he climbed into the fire box to tighten up the plug and then got the hell out of there pretty damned-fast! The fireman then spread the fire back over grate, in went a few shovelfuls of coal - and the loco was back in traffic with another load to Consett…I've heard from ex-Borough Gardens staff that this practice happened there too.

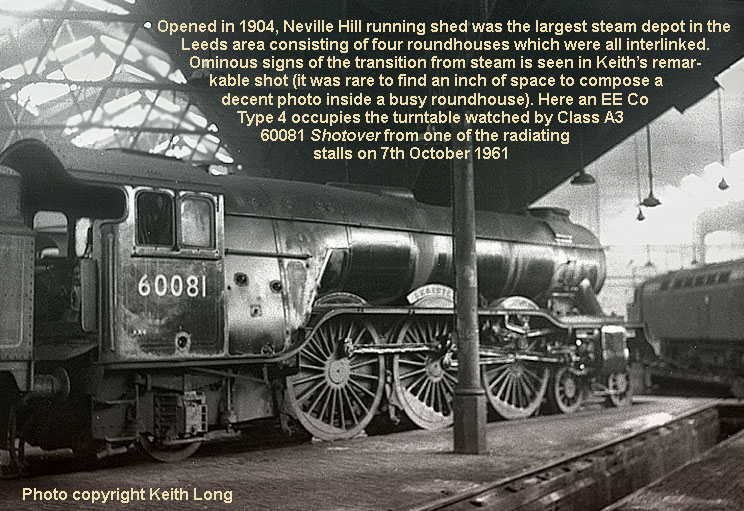

At this point I should tell you about the ten months I spent as a fitter at Neville Hill (NH). Just two weeks before I was due to finish my apprenticeship at Gateshead on 15th December 1959, the Staff Clerk Jack Drysdale informed me that as there were no immediate vacancies at Gateshead, would I be prepared to move? I agreed on condition that Gateshead remained my home depot and received a written reply with an assurance that I would be informed immediately the next time a vacancy at Gateshead occurred. Meanwhile I was told there were vacancies at Hillhouse (Huddersfield) and Low Moor (Bradford). I opted for Low Moor and arrangements were put in hand. However, three days later I was informed that a vacancy had arisen at Neville Hill, which suited me even better, and after travelling down to Leeds to see Mister Walker the Shedmaster, arrangements were made for me to go there instead. I started at Neville Hill just a few days before Christmas on 21st December 1959 by which time I had just missed the closing down of the Leeds tramway system on 7th November, which, by the way is another hobby of mine.The Railway found me digs not ten minutes walk from the depot, and amongst the first men I got to know at NH was Cecil Leng, George (TUG) Wilson and Charlie Salter. These three lads were also new to NH, having been displaced upon closure of Starbeck (Harrogate) in September 1959. Amongst the other displaced men was Norman Horsfield and another chap, whose name escapes me now - both from Selby shed which had closed in October 59. All in all, the lads at Neville Hill were a canny bunch and we all got on well together. One of NH's comedians was Jimmy Hackett the turner, who provide much light relief…his impersonation of a man playing bowls in the machine shop was side-splitting - 'Old Mans Rugby!' he used to call it. Harold Franks was another character who constantly regaled us about the time he was a tram driver for Leeds Corporation. At the end of the shift, seeing him getting washed up was a sight to behold. He was thin on top and used to scrub his head with two stiff bristled scrubbing brushes (the type used on floors). Len Phillipson was another pal; he came from Goole Shed and we were reunited years later at South Gosforth DMU depot and then on returning to Heaton HST/DMU Depot we just carried on as normal. I always called him my 'Fellow Neville-Hillian' and we still keep in contact today…he lives close by.

(Above-Below) Two fine studies by former signalman Keith Long of NH's Class A3's - No 84 Trigo on 22nd April 1961 and No 81 Shotover on 7th October 1961 - two of NHs famous five. Like Haymarket 64B, NH 55H was always noted for its well turned-out Pacific type locos. Click here to visit Keith's excellent 'Cabsaab900' Flickr site; it contains several shots of both steam and diesel traction at NH.

Neville Hill depot was split in two; one half of the maintenance staff looked after steam locos and the other half was ensconced in the new DMU shed. Our tool room at NH was well equipped with a variety of heavy gear to maintain the Iron Horse. However, the main resident in the tool room was Herbert the cat, who was well looked after by all the staff with both food and milk. One day one of the lads commented - 'I'm sure Herbert is pregnant!'

Sure enough, some weeks later at 2am in the morning Herbert presented us with four kittens. After some weeks the kittens were spoken for and duly taken home. After some days, however, it was noticed that Herbert was missing which was odd for him (her) since she never strayed far from the tool room. I was on the afternoon shift when a tearful Harold Franks told me that Herbert had been found dead. It appeared that she had been hit by an engine and had just crawled away to die. She was placed in a cardboard box and cremated in No 36's firebox. Not surprisingly, the lads were most upset - Herbert had been such a friendly animal.

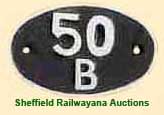

(Above) Class A1 60131 Osprey (with nameplates removed) and Class A4 60004 William Whitelaw were photographed at Neville Hill shed Leeds on 18th September 1965. These two East Coast pedigrees were streets ahead of the Thompson Pacifics; the A4 was supreme to the end, but both locos were capable of reaching 100mph. As a point of interest the A1s and the early A2s were known as Peppercorns and Thompsons. It looks as if my favourite Q6 63449 has shoved her nose in here. Keith Long adds - '60004 is been cleaned for the RCTS's 'Blyth and Tyne Railtour' the following day...' (Insets) Sheffield Railwayana Auctions recently sold a Neville Hill shedplate (50B from 1948 to February 1959) before the code was transferred to Hull Dairycoates between February 1959 and June 1967 to steam, totally in September 1970. The ex-NER shed at Neville Hill became 55H and and was home to around 80 locos, including five A3s, five named B1s, and five Hunts. The ex-NER shed Hull Dairycoates, formerly 53A, had an allocation of 90 locos when it took over this

(Insets) Sheffield Railwayana Auctions recently sold a Neville Hill shedplate (50B from 1948 to February 1959) before the code was transferred to Hull Dairycoates between February 1959 and June 1967 to steam, totally in September 1970. The ex-NER shed at Neville Hill became 55H and and was home to around 80 locos, including five A3s, five named B1s, and five Hunts. The ex-NER shed Hull Dairycoates, formerly 53A, had an allocation of 90 locos when it took over this  code. Chris adds - Neville Hill was always noted for the excellent cleaning of its five A3s Nos 36,74,81,84 and 86. (Right) Sheffield Railwayana Auctions also sold this Tyne Dock shedplate (54B from 1948 to October 1958). This ex-NER shed had around 50 locos during the time it used this code. It became 52H in 1958 up to closure to steam in September 1967. Tyne Dock was the ancestral home of all Q7 locos, albeit hated by footplate staff and fitters with three sets of valve gear between the frames...not an easy loco to work on.

code. Chris adds - Neville Hill was always noted for the excellent cleaning of its five A3s Nos 36,74,81,84 and 86. (Right) Sheffield Railwayana Auctions also sold this Tyne Dock shedplate (54B from 1948 to October 1958). This ex-NER shed had around 50 locos during the time it used this code. It became 52H in 1958 up to closure to steam in September 1967. Tyne Dock was the ancestral home of all Q7 locos, albeit hated by footplate staff and fitters with three sets of valve gear between the frames...not an easy loco to work on.

Life at NH revolved round three shifts Morning, Noon and Night…it makes you think of Von Suppe's overture of that name! Your position on the roster determined what you were doing: running repairs or standing repairs - the latter being the locos withdrawn from service for maintenance purposes. One day one of the A3s failed because the steam pipe for the steam sands from the manifold split and burnt the drivers hand as he was testing the sands prior to departure from the depot. It was enough to keep him off work for a while. Harry the Coppersmith made a brand new steam pipe which was fitted and the loco returned to traffic. A few days later a directive was issued by GHQ at York to all depots with A3s, the dictate  being that the steam pipe from the manifold to the operating valve (which was down by the reverser handle) was to be removed, annealed (softened) and refitted which we duly did at NH.

being that the steam pipe from the manifold to the operating valve (which was down by the reverser handle) was to be removed, annealed (softened) and refitted which we duly did at NH.

Going home for the weekend I would usually use two trains; either the 09-15 'North Briton' to Newcastle on Saturdays, which was usually diagrammed for any one of NH's A3s. One Saturday the booked loco failed on depot and the substitute loco turned out to be a B16/1. Although we departed Leeds on time I had some misgivings, but wonder of wonders we arrived at York one minute early. At York the B16/1 was changed for a grimy-looking V2 - and believe it not, we arrived at Newcastle on time. If I was going home on a Friday, my usual train was an afternoon Liverpool-Newcastle (16-32 out of Leeds) via Harrogate and Ripon which arrived in Newcastle just after 19-00. The interesting thing about this afternoon train is that it was always worked by the same two locos - 'Jubilee' class 45695 Minotaur of Holbeck and Class A2 60539 Bronzino of Heaton. Sunday was a day of rest for these two and entailed a boiler washout and repairs. In the morning, 539 would work the 08-55 Newcastle-Liverpool via Ripon and Harrogate to Leeds, involving reversal at Leeds New, where 45695 would back on to the train for the remainder of the journey to Liverpool.

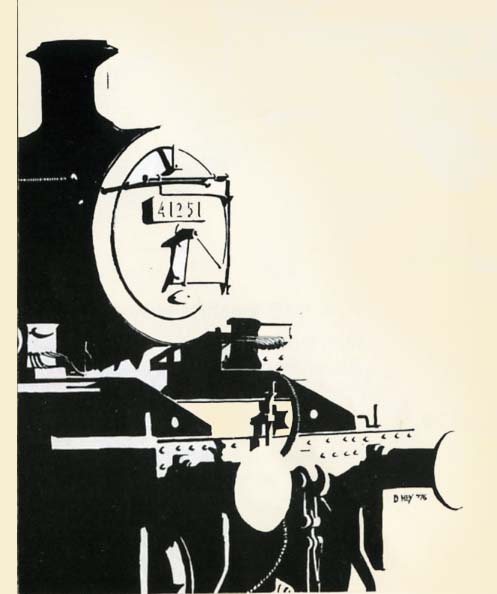

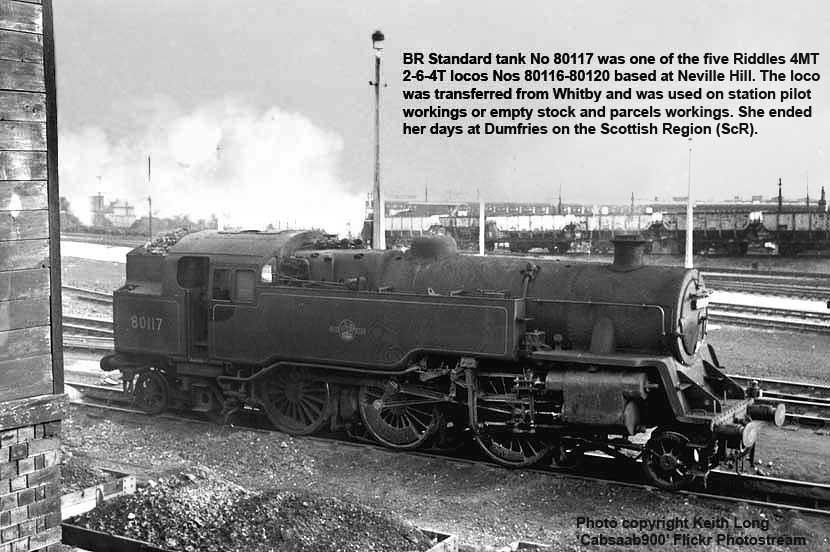

NH had rich variety of locos stationed there, the stars of the steam side being the five Gresley A3s consisting of Nos 36, 74, 81, 84 and 86. Always immaculately turned out, these five were exceptionally well maintained and used mainly on turns to Newcastle. There were also some Thompson B1s used on turns to Hull plus a large number of Raven B16/1s, many of which did very little work. They were accompanied by that battered old warhorse (three cheers) the Q6. As I recall it two arrived in the exodus from Selby. Other locos were J39s, Ivatt 2MT tank locos 41251 and 41282, and a few Ivatt 4MT tender locos known as 'Flying Pigs' - not forgetting the five Riddles 4MT 2-6-4 tank locos Nos 80116, 80117, 80118, 80119 and finally 80120.

Carole Gibson writes - 'A big thank you for the wonderful pictures of steam trains. My father worked at Neville Hill Shed from the age of 13/14 as a cleaner; then he made fireman and finally driver - all during the steam era. My brother and I were brought up nearby and I can remember going to pick up his wages and passing the huge turntable. I am now 75 and my father died in 1975 but it was lovely to see old pictures of the past. My father was called George Bernard Hillyard and we used to live on Pontefact Avenue which overlooked the cutting through which the steamers travelled. By the way he hated the diesel trains, never did take to them...and he looked forward to his retirement in the end. I keep looking for these wonderful pictures of the past. Many thanks, Carole…'

(Upper Left-Below) Pen drawing of Ivatt 2-6-2T No 41251 complete with Silvertown Mechanical Lubricators on either side of the smoke box door. (Below) BR standard 2-6-4T No 80117 was transferred from Whitby and used on station pilot workings or empty stock and parcel train workings.She ended her days at Dumfries in the Scottish Region.

If a Neville Hill fitter was rostered for Saturday night duty on running repairs, he and his mate were the only ones in the shed. The other night staff on duty worked in the DMU shed. On the wall, by the 70-foot turntable, was an engine departure board which was maintained by the Running Foreman, who was in charge of the footplate staff. This board indicated the departure times for each engine, and on Saturday nights the board was always chock-full right up to Sunday dinner time. The practice of the night duty fitter was to work on the engines up to the 09-30 departure to take the load of the dayshift. I recall one particular night during the week when a derailment occurred outside the shed door. The pony wheels of a V2 had derailed and boxed the job up. I should mention that the pony wheels on an engine such as a V1, V2, V3 and V4 were the carrying wheels at the front end under the smoke box. On the type V1s and Pacifics, the wheels under the cab were called radial wheels. Anyway, at the request of the Running Foreman, we got the V2 back on the rails and into the shed, and gave her a thorough examination to see if she had sustained any damage, and I'm glad to say there was none. The incident was duly logged for the attention of the Mechanical Foreman, who was furious that HE had not been called out…seemingly we had deprived him of an extra shift payment! The very next night, however, we were able to make amends when the pony wheels of another V2 derailed in the very same spot and the Running Foreman asked us to the honours again. We told him that the Mechanical Foreman had given us strict instructions to call HIM out in the event of a derailment, and so we left the engine just as it was until EL SUPREMO arrived about two hours later. It's a good job that there was another way in and out of the shed.