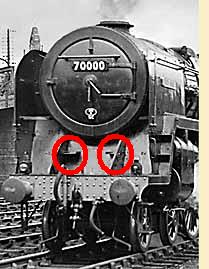

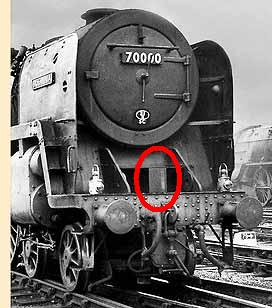

(Above-Below) Sporting a Stratford shedplate (30A) on the smokebox door, the doyen of the BR Standard Class 7MTs, No 70000 Britannia, heads a southbound train through Holgate Junction York. (Below) Following an accident involving No 70026 on the Western Region the smoke deflector handrails were replaced by grab holds on the WR's allocation of Class 7MTs, and thereafter the Eastern Region's batch was similarly treated, including 70000, which can be clearly seen in Keith Long's shot of 70000 following arrival at York with a train from Great Yarmouth on Saturday 23rd September 1961.

The Class 7MT Pacific was the first of twelve new 'standard' classes, however the full complement of fifty five locomotives Nos 70000-70054 were far from 'standard'. I havebeen contacted by the eagle-eyed Derek Dean, who describes 14 visible modifications of No 70000 in the above two photos at York alone!

Now I ask you…who would have thought it?

This is worth further investigation, I thought and so I am indebted to Derek Dean for submitting an article on the subject. He writes - 'David, if you believe that a detailed explanation of the quoted modifications will be of interest to enthusiasts in general, and to railway modellers especially, then that's what we shall do...'

CHANGING STANDARDS

by Derek Dean

Designed at Derby and built at Crewe, with additional sections designed at Brighton, Doncaster and Swindon, the basic ethos of the new BR Class 7MT 'Britannia' Pacific was simplicity in construction, lower coal consumption, and longer mileage between classified repairs. The Class 7MT was a straightforward 2-cylinder design, and probably more of an amalgam of the former 'Big Four' companies engines than any other Standard class. The boiler, cylinders and valve gear came from LMS practice, the main frame and trailing truck from the Southern Railway, and the crossheads and slidebars were influenced by the LNER, whilst the GWR inspired the mechanical lubrication and various other steam fittings.

The name 'Britannia' was thought of by Rev Eric Treacy, but the engine was nameless when first seen in black livery during a period of initial testing on January 2nd 1951. The design of the engine was attained by a team of eight men led by RA Riddles, RC Bond and ES Cox, all three being ex-LMR men...hence it came as no surprise that a decision was taken to build the new BR Standard Pacific at Crewe Works.

The design was augmented by using other Regional Drawing Offices at Derby, Brighton, Swindon and Doncaster, each having some input and involvement in the completed design. The locomotives were expected to have a life-span of 40 years, whereas in reality, the class only had a really useful span of 10 years in service and would no doubt have been banished some way before 1967, but for the fact of the cost of the class.

of the class.

The design is generally accredited to Robin Riddles, but the main mechanical ideas came from ES Cox, although he did not succeed in his wish to build the locomotives with bar frames. These would have been much stronger than the frames used, which were of 1.25 in plate and horizontal rack stays, this being due to the fact that Britain's Locomotive Works weren't equipped to build such engines.

The boilers were based on the 'Coronation' class Pacifics and the angle of the sloping fronts 67 degrees, a figure decided upon by Air Dynamic Tests. After successful tests, 'Britannia' returned to Crewe Works for final adjustments and after a repaint in the chosen Brunswick Green livery, the nameplates were fitted.

(Above Right-Below) The doyen of the class, No 70000 Britannia, was photographed by Railway Cameraman Keith Long on the service line at London Liverpool Street station on 30th August 1960. Following the introduction of the BR Standard Class 7MT locomotives to traffic, several modifications were made to improve their performance, many of which were clearly visible, others less so - therefore for the benefit of younger modellers a list of the detailed alterations are featured in a numbered sequence below. However it would be wrong to describe them all as modifications, more like additions-improvements, such as the fitting of cab sheets, but they are included here to help the discerning modeller, artist and model engineer replicate a particular period during the class's career between 1951-1968. (Below) A most magnificent live steam 3½" Gauge Locomotive 70000 Britannia, built to the highest possible standard with immaculate detail to challenge the best show model of its class. This superb model (including a glass display case) went under the hammer for £7,000 at a Great Western Railwayana Auction in May 2012...a step-by-step analysis of the various modifications of the BR Class 7 Pacific can be found further down the page..

introduction of the BR Standard Class 7MT locomotives to traffic, several modifications were made to improve their performance, many of which were clearly visible, others less so - therefore for the benefit of younger modellers a list of the detailed alterations are featured in a numbered sequence below. However it would be wrong to describe them all as modifications, more like additions-improvements, such as the fitting of cab sheets, but they are included here to help the discerning modeller, artist and model engineer replicate a particular period during the class's career between 1951-1968. (Below) A most magnificent live steam 3½" Gauge Locomotive 70000 Britannia, built to the highest possible standard with immaculate detail to challenge the best show model of its class. This superb model (including a glass display case) went under the hammer for £7,000 at a Great Western Railwayana Auction in May 2012...a step-by-step analysis of the various modifications of the BR Class 7 Pacific can be found further down the page..

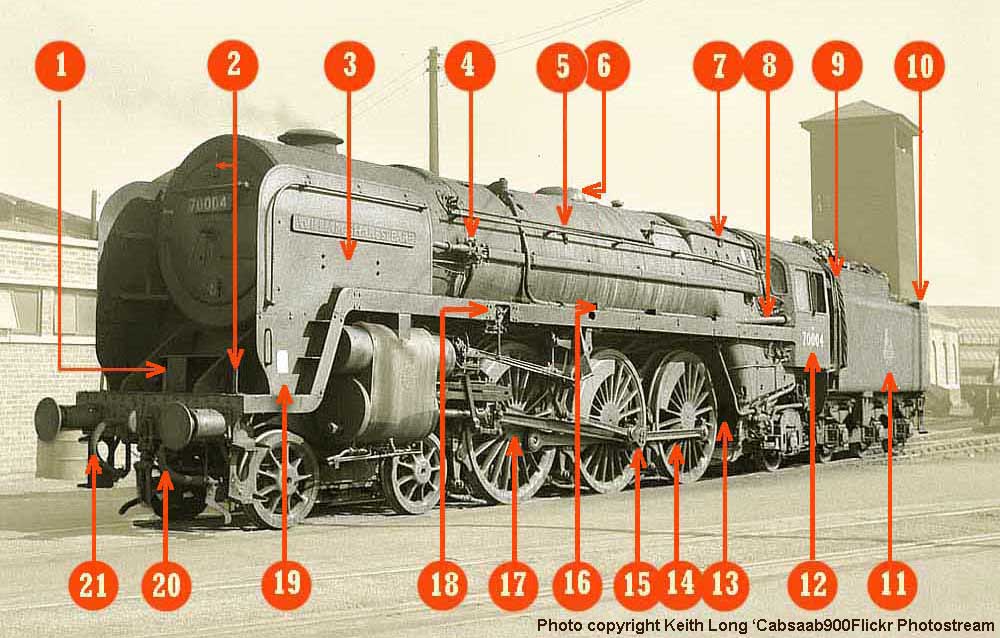

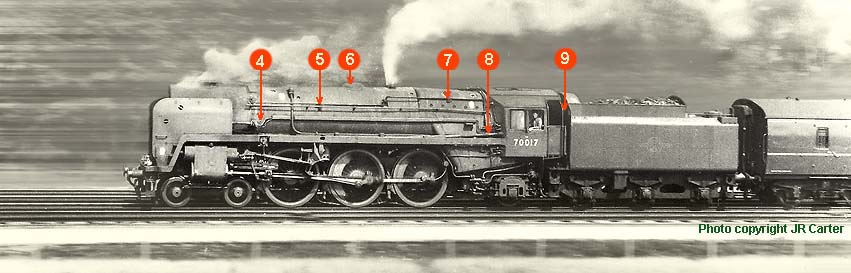

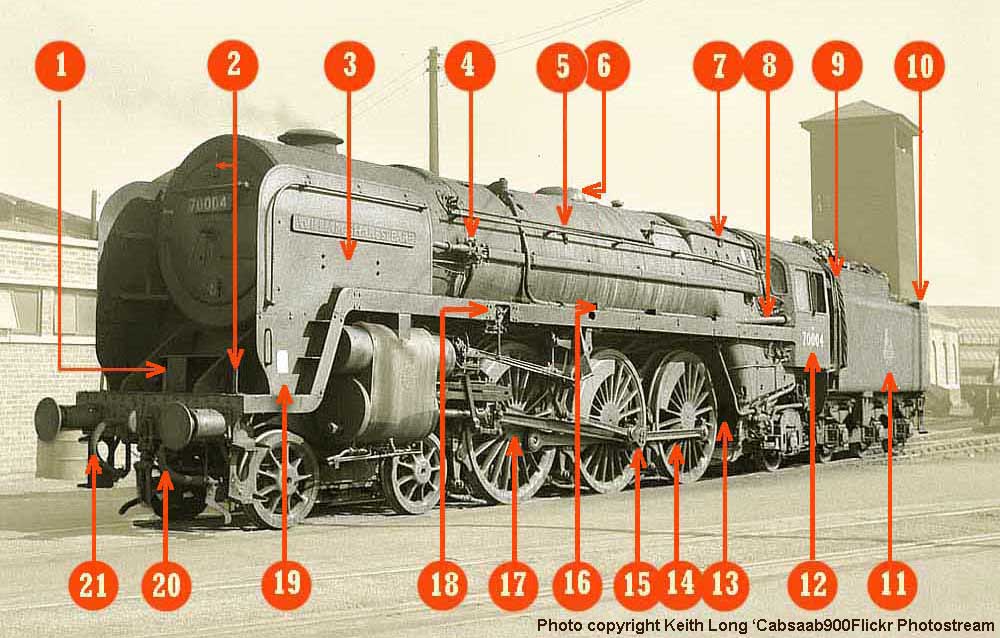

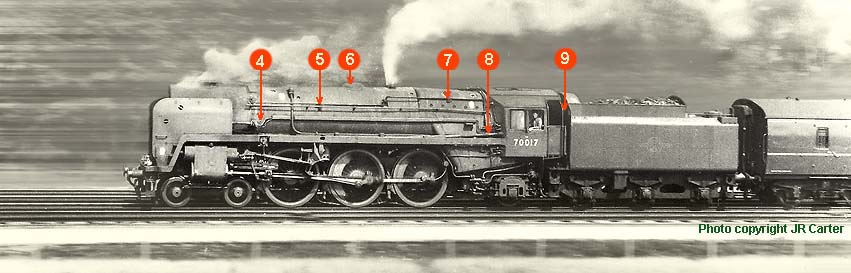

(Above) 1. FRONT STEP; 2. LAMP IRONS; 3. SMOKE DEFLECTORS; 4. EXHAUST EJECTOR MOD; 5. FRONT REGULATOR ROD SUPPORT BRACKET; 6. DOME COVER; 7. REAR REGULATOR ROD SUPPORT BRACKET; 8. REVERSE ROD RETURN SPRING COVER; 9. CAB SHEET MOD; 10.TENDER STEP; 11.NEW BR TOTEM; 12.LIVERY; 13.SPEEDOMETER; 14.COUPLING RODS; 15.LNER-LMSR RETURN CRANK; 16.SANDBOX LIDS; 17.AXLE; 18.LUBRICATION PUMP OPERATING ROD; 19.POWER WARNING FLASHES; 20.ATC/AWS and 21.VACUUM PIPE.

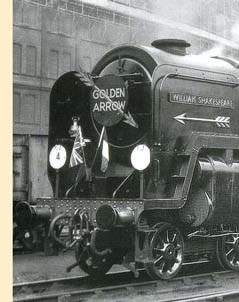

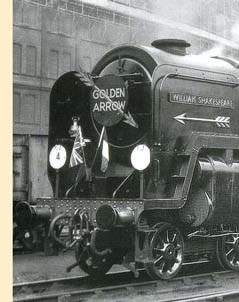

(Below) In all fairness to 'Rail Camerman' Keith Long, here is the original photo of 'Britannia' Class 7MT No 70004 William Shakespeare at Willesden shed on 16th September 1961. Built at Crewe Works and delivered in March 1951, 70004 was exhibited at the Festival of Britain, then allocated to Stewarts Lane until 1958; she worked the 'Golden Arrow' on a regular basis and continued to carry the fixing bolt holes for the ornamental arrow in her smoke deflectors until early in 1965 when accident damage to the offside smoke deflector meant that a new sheet and stays were fitted at Darlington Works. After leaving the SR she spent time at Trafford Park, Willesden, Crewe North and Stockport until been allocated to her final shed at Kingmoor in 1967. Withdrawn in December 1967 she was scrapped at TW Ward of Inverkeithing in April 1968...check out Keith Long's superb 'Rail Camerman' Page 47 on the left-hand menu.

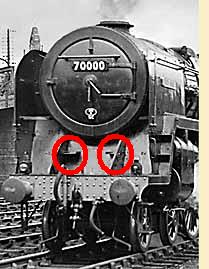

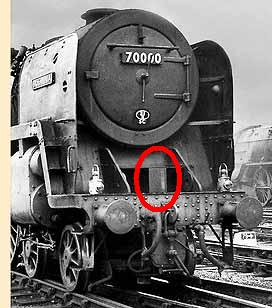

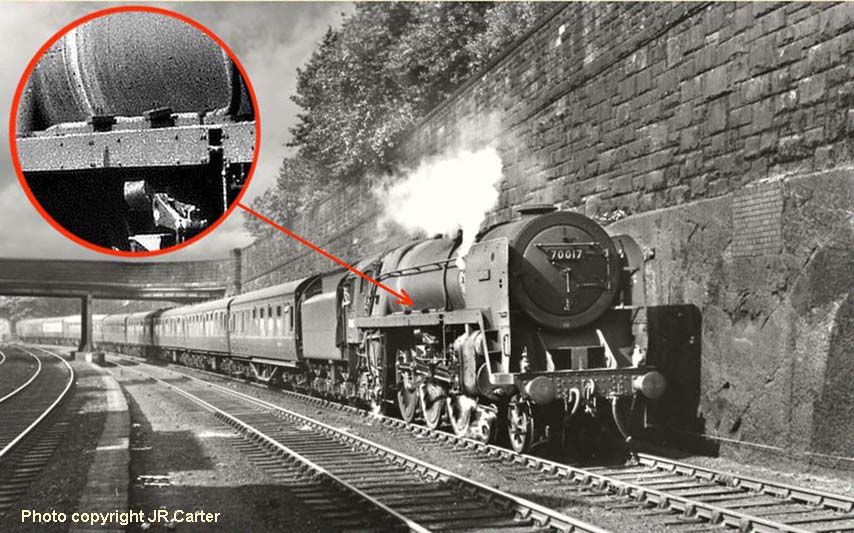

1. FRONT STEP MOD: The locomotives on the GE section bore many headboards on a daily basis, such as the 'Norfolkman' and 'East Anglian' etc. However, in the original design only two separate footsteps were provided beneath the smokebox door (see inset left) and engine crews had difficulty in reaching the topmost lamp iron to locate the headboards. Stratford Loco devised a simplified platform supported by a single bracket, which can be seen in the shot (above) of Britannia class No 70034 Thomas Hardy arriving at Liverpool Street with the 'East Anglian'. Built at Crewe to Order E483/228, 70034 entered service at Longsight in December 1952, but was soon transferred to the Eastern Region to

1. FRONT STEP MOD: The locomotives on the GE section bore many headboards on a daily basis, such as the 'Norfolkman' and 'East Anglian' etc. However, in the original design only two separate footsteps were provided beneath the smokebox door (see inset left) and engine crews had difficulty in reaching the topmost lamp iron to locate the headboards. Stratford Loco devised a simplified platform supported by a single bracket, which can be seen in the shot (above) of Britannia class No 70034 Thomas Hardy arriving at Liverpool Street with the 'East Anglian'. Built at Crewe to Order E483/228, 70034 entered service at Longsight in December 1952, but was soon transferred to the Eastern Region to  join the stud of 'Britannias' based at Norwich (32A) for Great Eastern main line services. It was transferred back to the LMR again in March 1963, and following withdrawal from Kingmoor in May 1967 was broken up by J McWilliam, Shettleston in October that year. (Below) Stratford's support bracket can be seen in this photo of 70003 John Bunyan heading a down Norwich express through Manningtree on 18th April 1954. This modification appeared around 1953-1954 and sufficed until Crewe Works devised a stronger, deeper version with a larger bracket. No 70000 was fitted with this full modification (right) at Doncaster Loco during December 1956. This modification superseded both the original and the Stratford type on all members of the class.

join the stud of 'Britannias' based at Norwich (32A) for Great Eastern main line services. It was transferred back to the LMR again in March 1963, and following withdrawal from Kingmoor in May 1967 was broken up by J McWilliam, Shettleston in October that year. (Below) Stratford's support bracket can be seen in this photo of 70003 John Bunyan heading a down Norwich express through Manningtree on 18th April 1954. This modification appeared around 1953-1954 and sufficed until Crewe Works devised a stronger, deeper version with a larger bracket. No 70000 was fitted with this full modification (right) at Doncaster Loco during December 1956. This modification superseded both the original and the Stratford type on all members of the class.

2.LAMP IRON MOD. Lamp Irons have always been an integral part of locomotive operating practice, but probably not much noticed by enthusiasts, so lets have a closer look at those on the Britannia Class.

I have broken these down into six different categories: 1. LMR Irons - generally 4 inches long; 2. GER Irons - generally 6 inches long enabling the white disc to be used; 3. GWR Irons - quite obviously different in size and shape; 4. SR Irons - the type referred to were made to fit on the smoke deflector stay; 5. Long Irons - seen on early SR Locos, and only on 70004/70014 and finally 6. Repositioned Irons - all engines modified.

LMR Lamp Irons were fitted to new engines until about May 1951 when the longer GER section irons were adopted on Nos 70000-70014. The LMR type was then applied to Nos 70031, 70032 & 70033, which were the only true LMR engines, and then from 70042 onwards up to the last members of the Class, including those numbered 70050 to 70054 all of which were allocated in Scotland…all engines would eventually have used these irons.

GER Lamp Irons had to be swopped with the initial LMR type on Nos 70000 to 70009, thereafter Crewe Works were building the engines with them already fitted. Twenty three locos worked on the GE section, the full list comprised of 70000, 70001, 70002, 70003, 70005, 70006, 70007, 70008, 70009, 70010, 70011, 70012, 70013, 70030, 70034, 70035, 70036, 70037, 70038, 70039, 70040, 70041 & 70042, this list does not include 70015 & 70016 which were briefly allocated to Stratford 30A, in 1952 and into 1953.

GWR Lamp Irons were applied to the 15 Locos on the WR lines; these were fitted by Crewe in production, and were the same type as those used all over the GWR system. No 70015 Apollo had GWR Lamp Irons, but was loaned to the LMR and used on the GE section before arrival at Old Oak in September 1953.

SR Lamp Irons had to be fabricated to suit the Britannia Class, being fitted onto the lower stays of the smoke deflectors, and these could be seen on Nos 70004, 70009, 70014, 70017, 700023, 70024, 70028, 70029, 70030 & 70034 (see inset left of 70004 heading the 'Golden Arrow').

SR Lamp Irons had to be fabricated to suit the Britannia Class, being fitted onto the lower stays of the smoke deflectors, and these could be seen on Nos 70004, 70009, 70014, 70017, 700023, 70024, 70028, 70029, 70030 & 70034 (see inset left of 70004 heading the 'Golden Arrow').

Long Lamp Irons (right) were only to be seen on two Britannia Class Nos 70004 and 70014 when both locos were allocated to Stewarts Lane MPD for working the prestigious 'Golden Arrow' from London to Dover and Folkestone. This modification was devised to prevent the train lamps from 'blowing out' in the winter months, which might sound absurd, but records show that a signalman on the route had stopped the train on a number of occasions because he was unable to identify which train was coming towards him in the dark. The problem was deemed serious, but the matter was not fully resolved until the Foreman Fitter at Stewarts Lane thought of using the long irons; this type having been used on many Southern Railway locos in previous years.

Long Lamp Irons (right) were only to be seen on two Britannia Class Nos 70004 and 70014 when both locos were allocated to Stewarts Lane MPD for working the prestigious 'Golden Arrow' from London to Dover and Folkestone. This modification was devised to prevent the train lamps from 'blowing out' in the winter months, which might sound absurd, but records show that a signalman on the route had stopped the train on a number of occasions because he was unable to identify which train was coming towards him in the dark. The problem was deemed serious, but the matter was not fully resolved until the Foreman Fitter at Stewarts Lane thought of using the long irons; this type having been used on many Southern Railway locos in previous years.

Repositioned Lamp Irons, refers to all of the class from 1963 onwards. This final modification was made in order to safeguard enginemen when working in areas with overhead catenary; the topmost iron was lowered to a position down the smokebox door and the centre iron was realigned also to suit. This configuration can be seen in Jim Carter's photo (below) of 70045 Lord Rowallan heading an 'up' train at Chester...check out Jim Carter's superb 'Footplate Cameraman' Page 32 on the left-hand menu.

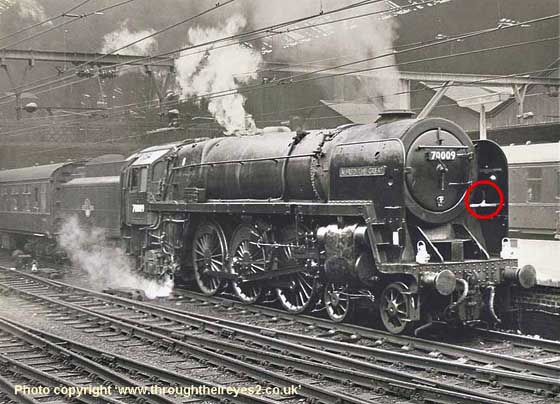

(Above-Below) Evidence of the short period working on the Southern Region from May to October 1951 are the SR lamp irons fitted to the lower stay of the smoke deflectors of 70009 Alfred the Great. The loco was allocated to Nine Elms MPD on loan for trials on the Bournemouth Belle. Here 70009 is back on familiar Eastern Region territory at Liverpool Street station. (Below) This ER Morten shot shows 'Britannia' class No 70014 Iron Duke heading the 4.00pm Manchester Central-St Pancras (SO) at Peak Forest on 17th August 1958. Note the height of the express lamp headcode display which is mounted on the SR type elongated lamp irons either side of the buffer beam; also just visible is one of the SR irons on the lower stay of the smoke deflector.

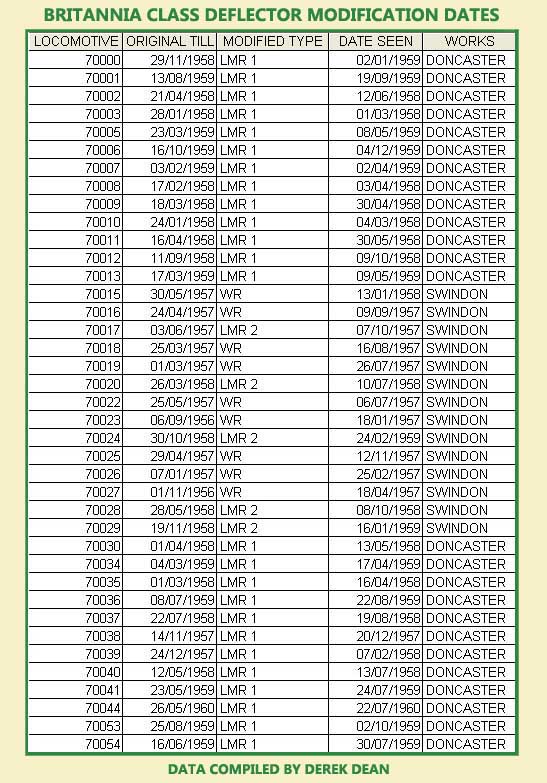

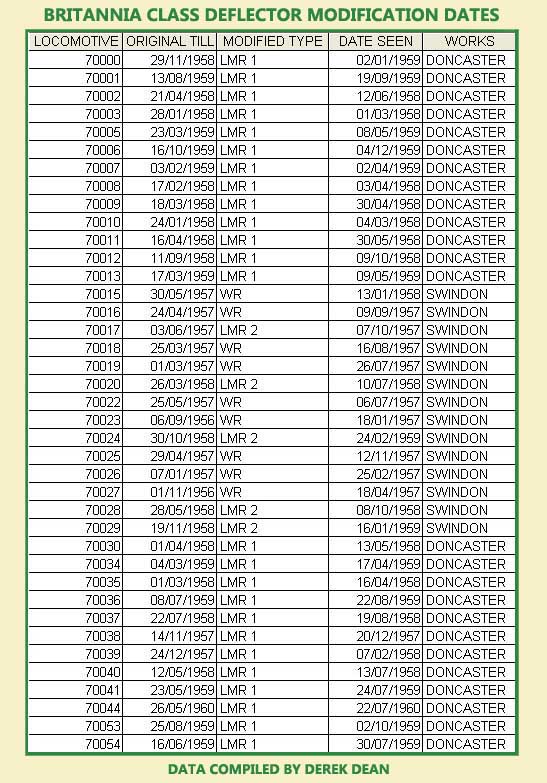

3. SMOKE DEFLECTOR MOD. We will look at four categories in this section: 1. Original type - 16 engines were not changed; 2. LMR type 1 - 25 engines received this modification; 3. LMR type 2 - 5 locos were so treated, and finally 4. WR type - 9 engines received this design.Original type - those that were basically maintained at Crewe Works, and included Nos. 70004, 70014, 70021, 70031, 70032, 70033, 70042, 70043, 70045, 70046, 70047, 70048, 70049, 70050, 70051 & 70052 (total 16). Of note, that although No 70021 was on the WR for 7 years, she was not changed in any way, and No 70042 was allocated to GE section for almost 5 years, yet it wasn't altered at all. The handrails on the smoke deflectors were sometimes referred to as 'the dangerous handrails' by engine crews in direct reference to the decision made to remove them on safety grounds.

treated, and finally 4. WR type - 9 engines received this design.Original type - those that were basically maintained at Crewe Works, and included Nos. 70004, 70014, 70021, 70031, 70032, 70033, 70042, 70043, 70045, 70046, 70047, 70048, 70049, 70050, 70051 & 70052 (total 16). Of note, that although No 70021 was on the WR for 7 years, she was not changed in any way, and No 70042 was allocated to GE section for almost 5 years, yet it wasn't altered at all. The handrails on the smoke deflectors were sometimes referred to as 'the dangerous handrails' by engine crews in direct reference to the decision made to remove them on safety grounds.

LMR type 1 had the handrails removed, being replaced by two handholds with backing cups, the first to be modified was No 70038 (right) which entered Doncaster Works in November 1957, and emerged in December suitably modified. This started off a programme whereby all GE section engines were altered in a relatively short space of time 2 years. Introduced to traffic on 29th January 1953, to Order No E483/228, No 70038 Robin Hood's career followed a familiar pattern for the GE's 'Britannias' with allocations to Stratford (30A), Norwich (32A), March (31B) and then to Immingham (40B), having just been overhauled, before ending its days at Carlisle (12A) on the LMR from where it was withdrawn in August 1967. 70038's time at 40B Immingham was spent mostly on Kings Cross-Cleethorpes express turns, though it was doubtless called upon to work the Grimsby-London Fish traffic. This photo of 70038, in a typically-grimy state for the time, was taken at Carstairs on the LMR towards the end of its career, and shows the lamp iron has been removed from the top of the smokebox door and repositioned further down to the right; likewise the centre iron on the buffer beam has been realigned to allow a display of one lamp over the other.

days at Carlisle (12A) on the LMR from where it was withdrawn in August 1967. 70038's time at 40B Immingham was spent mostly on Kings Cross-Cleethorpes express turns, though it was doubtless called upon to work the Grimsby-London Fish traffic. This photo of 70038, in a typically-grimy state for the time, was taken at Carstairs on the LMR towards the end of its career, and shows the lamp iron has been removed from the top of the smokebox door and repositioned further down to the right; likewise the centre iron on the buffer beam has been realigned to allow a display of one lamp over the other.

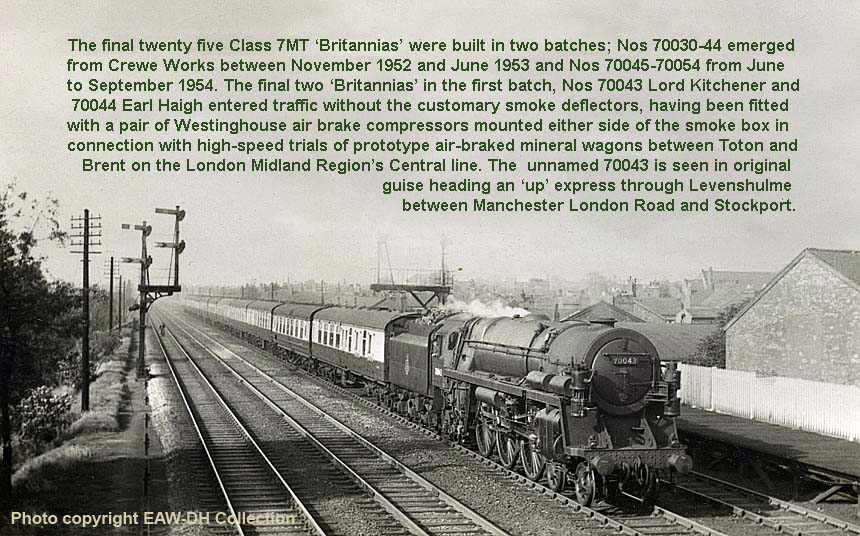

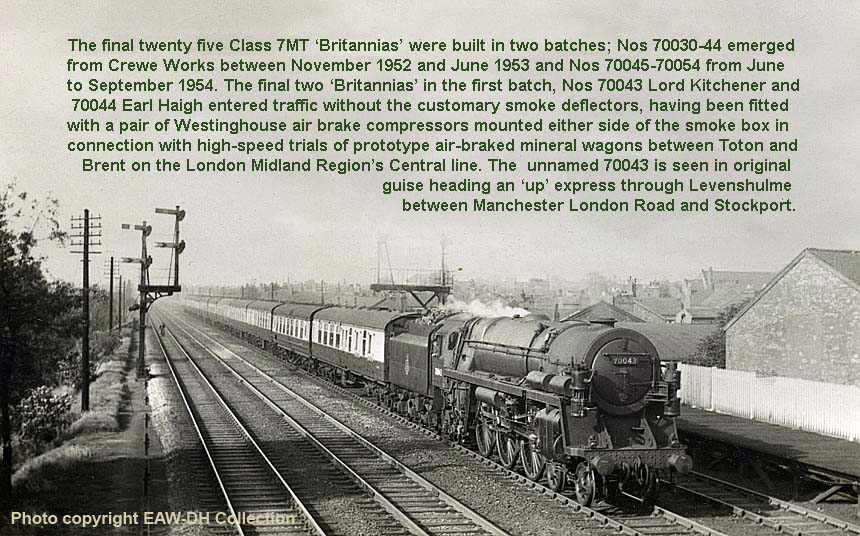

(Below) The last of the class to be treated with modified deflectors was No 70044 in July 1960, also at Doncaster. However, it is worth mentioning that 70044 was fitted with Westinghouse Brake Equipment from almost new and was not seen with smoke deflectors until March 1957. The other member of the class fitted with Westinghouse Brake Equipment was 70043 as seen below.

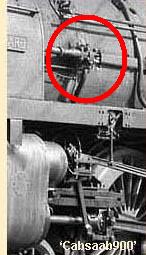

LMR type 2 were very similar to type 1, but without the backing cups, as seen on Nos. 70017, 70020, 70024, 70028 & 70029, these being modified at Swindon Works between late 1957 and early 1959 [see 70017 below]. I have found no evidence of why this type was chosen, and dates show that at the same time that No.70017 was being repaired, No.70025 was modified to WR type.

I have found no evidence of why this type was chosen, and dates show that at the same time that No.70017 was being repaired, No.70025 was modified to WR type.

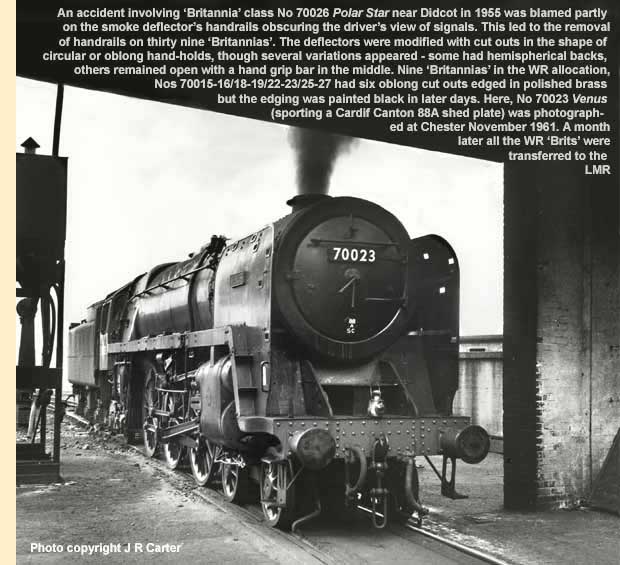

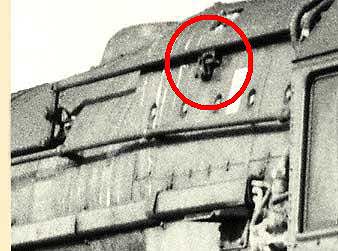

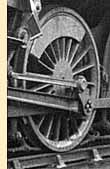

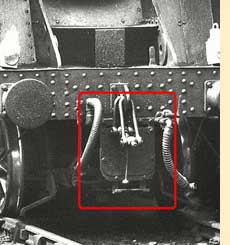

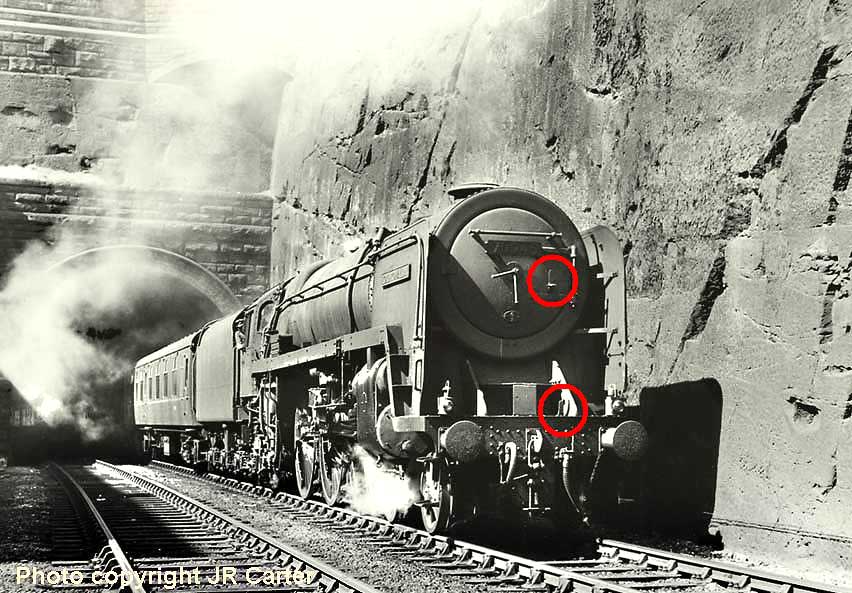

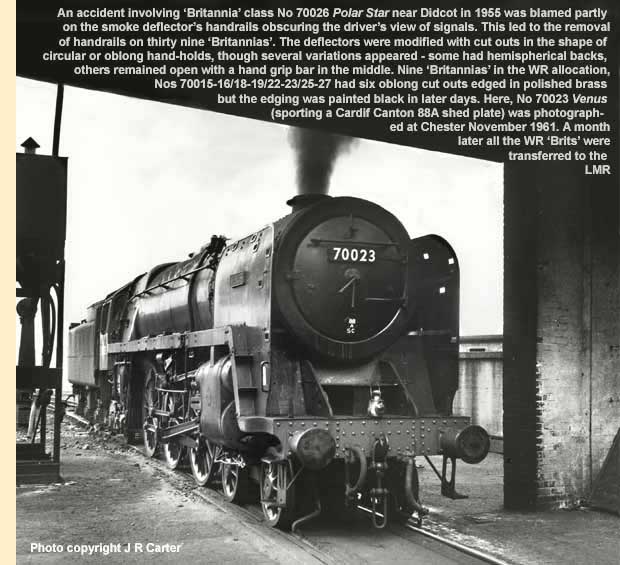

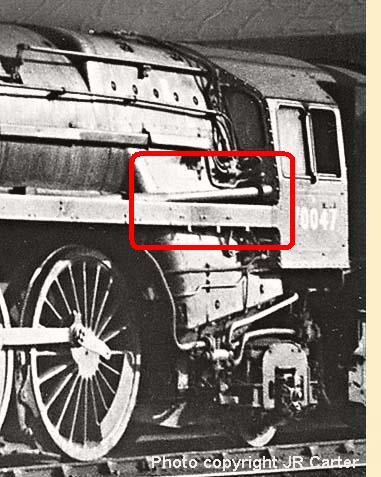

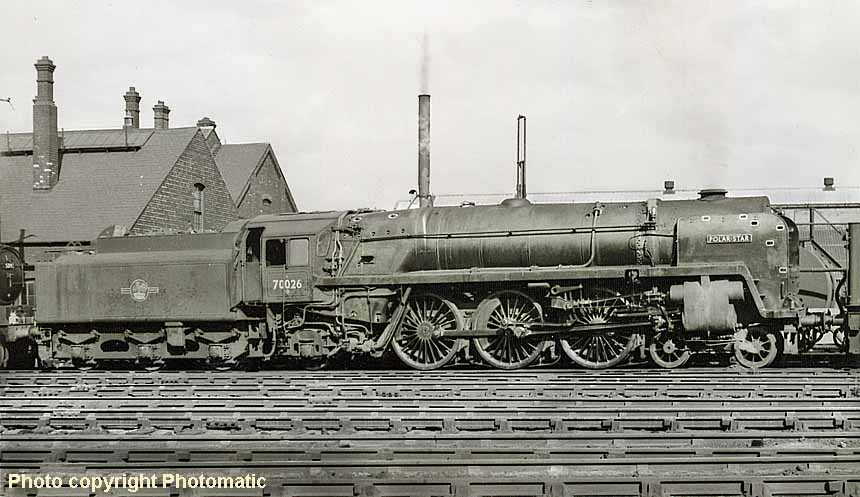

WR section Locomotives were altered at Swindon Works from early in 1957, when No 70023 (left) was modified. This close-up shot by JR Carter of 70023 not only shows the six brass-lined handholds, but also of interest is the lamp iron mounted at the top of the smokebox; this is a GWR type, whereas the lamp iron on the smoke deflector stay is of SR origin and the buffer beam carries a mix of LMR and GE irons (short and long respectively). The first engine allocated to the WR was No 70015 Apollo, which had the smoke deflector modification done 12 months later, having 6 cut-outs in each deflector sheet. The majority of these handholds were brass-lined, which added to the overall look of the WR engines, being usually kept in very clean condition by staff at Cardiff Canton MPD. The nine Locomotives were: 70015, 70016, 70018, 70019, 70022, 70023, 70025, 70026 & 70027. A spruced-up 70022 Tornado can be seen below at Cardiff Canton shed.

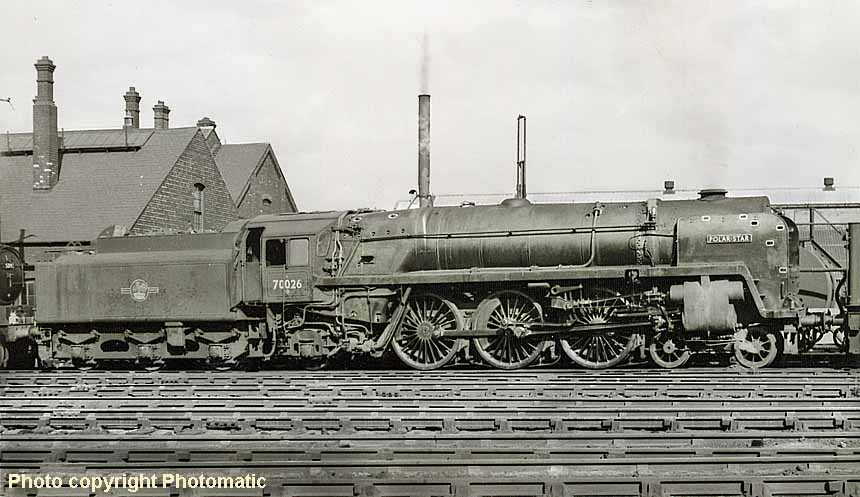

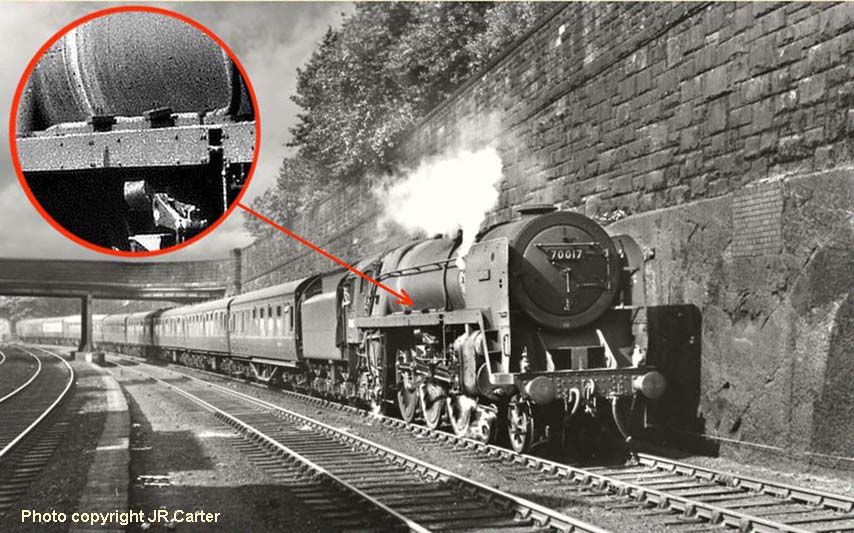

(Above-Below) The subject of smoke deflector modifications would fill a whole web page of its own, since a large number of variants appeared following the involvement of 70026 Polar Star in the Milton crash on 20th November 1955 in which 11 people lost their lives. Also known as the 'Didcot Accident', the enquiry concluded that the driver's view of relevant signals had been obstructed in part by the handrails on the smoke deflectors, although the Crash Investigation Committe also acknowledged other contributing factors. Their findings resulted in Swindon Works devising some modifications to improve the situation, hence many Britannias were fitted with a GW type deflector consisting of six handholds cut into the deflector, many with brass surrounds. Nine engines were modified in this manner, although oddly enough 70026 was not the first to be treated! However, Crewe Works did not modify any engines that went through Major Overhauls, giving the distinct impression that they did not concur with the Crash Committee's findings. Meanwhile Doncaster Loco modified most of the Britannias in due course of shopping, though

November 1955 in which 11 people lost their lives. Also known as the 'Didcot Accident', the enquiry concluded that the driver's view of relevant signals had been obstructed in part by the handrails on the smoke deflectors, although the Crash Investigation Committe also acknowledged other contributing factors. Their findings resulted in Swindon Works devising some modifications to improve the situation, hence many Britannias were fitted with a GW type deflector consisting of six handholds cut into the deflector, many with brass surrounds. Nine engines were modified in this manner, although oddly enough 70026 was not the first to be treated! However, Crewe Works did not modify any engines that went through Major Overhauls, giving the distinct impression that they did not concur with the Crash Committee's findings. Meanwhile Doncaster Loco modified most of the Britannias in due course of shopping, though  I'm not sure who decided upon the design for the majority of the class (25 of 39 were modified). It should be noted that 16 engines were not altered at all, and 5 locos had a different pattern with no backing to the handholds being modified at Swindon Works; these being numbered 70017, 70020, 70024, 70028 and 70029.

I'm not sure who decided upon the design for the majority of the class (25 of 39 were modified). It should be noted that 16 engines were not altered at all, and 5 locos had a different pattern with no backing to the handholds being modified at Swindon Works; these being numbered 70017, 70020, 70024, 70028 and 70029.

(Above) Footplate Cameraman, Jim Carter, took this shot of 70000 at York; the smoke deflectors on 70000 were modified on the 29th November 1958 and this photo shows the bulbous backing cup inside the deflector. (Below) Comparisons can be made with the raking light picking out the blank handhold of 70017 Arrow's nearside smoke deflector as the loco departs from Kettering; only five were so treated, 70020, 70024, 70028 and 70029 being the others. Digressing briefly, following complaints from crew about overfilling from water troughs, 70017 was unique in having a GWR dome fitted on the tender...this feature can be seen more clearly in the second view of 70017 departing Kettering below...

(Above) A superb panning shot of Britannia class 70017 Arrow at Winwick Junction. Introduced to traffic on 23rd June 1951, No 70017 became the first member of the class to be seen at Old Oak Common. This occurred because Nos 70015 and 70016 destined for the WR were on loan to the LMR at that time, however 70017's arrival was 'not appreciated' by WR enginemen. A complaint was made of overfilling of the tender from water troughs, and so Swindon Works fitted a large dome on the tender akin to the GWR 2-8-0 class. During its time on the WR 70017's average mileage was said to be 40-50,000 per annum which was well below those recorded by the class on other Regions. The smoke deflector modification was carried out by Swindon Works in October 1957, but rather than using six brass-lined handholds the modification comprised two handholds without the LMR type 1 backing cups. The Exhaust Ejector was fitted with a valve and later lowered, although not repositioned following Arrow's transfer from the WR at the end of June 1958. 70017 was one of the engines to fail in service with broken coupling rods, yet it was transferred to Salisbury for four weeks in June 1953 to cover for the Merchant Navy locos which were out of service with axle problems of their own. SR type lamp irons were duly fitted at this time, which 70017 retained up to withdrawal in October 1966 after running into a freight train at Carlisle, whilst hauling empty coaching stock from Glasgow to Morecambe. Damage was not extensive, but considered uneconomical to repair. In contrast to the preceding photos of 70017 at Kettering, the dome cover (on the rear of the tender) has gone and the tender step is different; this is because 70017 had a swap of tenders with 70031 on which the tender step is the Swindon type. You can compare this to the LMR-type in the panning shot below...

(Below) 70002 Geoffrey Chaucer emerged from Crewe Works on 6th March 1951 destined for the GE section, where the engine averaged 85,000 miles per annum on duties such as 'The Norflokman', 'East Anglian' and 'Scandinavian'. This was the third member of the class, and as such was beset with initial problems: the low dome had to be changed; the axle mod was carried out and it suffered a mainframe fracture in June 1952. The smoke deflectors were modified in June 1958 and both the AWS equipment and Speedometer were simultaneously fitted by 25th March 1960, but no alterations to the Exhaust Ejector ever took place. No 70002 spent the best part of 10 years on the GE section, mainly at Stratford (30A) then latterly at Norwich (32A) followed by the well-trodden path of the ER's 'Britannias' with spells at March (31B) and finally Kingmoor in December 1963. The end almost came early for 70002 when it ran into a parcels train at Carlisle on 8th August 1964, but following repairs the loco survived a further two years before withdrawal came on 14th January 1967.

4. EXHAUST EJECTOR MOD. (Left & Right) Again we need to subdivide this item into 5 parts: 1. Original - majority of the class. 2. Valve fitted, with cabling back to cab; 3. Ejector lowered (with valve) and modified pipework; 4. Ejector lowered (without valve) after Swindon removed its equipment; 5. Repositioned - back to original position, but without valve.

Ejector lowered (without valve) after Swindon removed its equipment; 5. Repositioned - back to original position, but without valve.

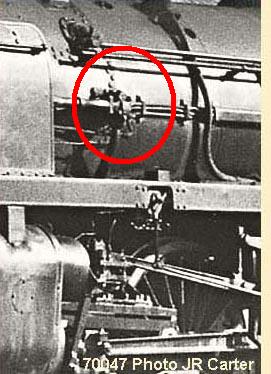

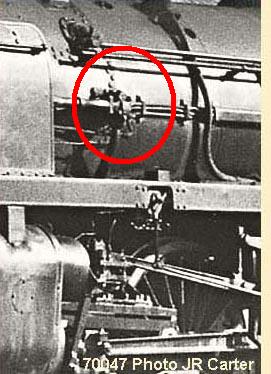

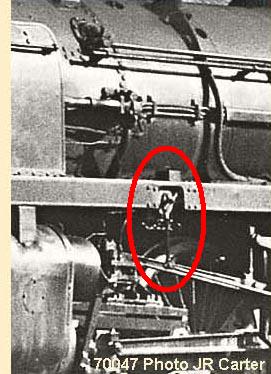

Swindon Works was looking into the steaming capabilities of the Britannia Class, and in 1958 considered fitting a double chimney. The outcome was to fit a solenoid valve to the top of the Exhaust Ejector assembly, which was operable from the cab, I believe to gain much better control over its operation. Unfortunately this only added to poor visibility afforded to the driver, which was the nearside position on BR Standards as opposed to offside on WR engines. Because of this Swindon then lowered the whole assembly, having to modify the pipework to reach the new position. When the locomotives were allocated away in 1961, Swindon removed their equipment. However, in some cases, but not all, the Exhaust Ejector was repositioned when back on LMR. Thus it was possible for a Western Region Britannias Nos 70015-70029 to be seen in all 5 different conditions, with the exception of No 70021 Morning Star, which retained its original state. For the discerning modeller, the truncated ducting of 70047 (left) has been discarded following examination whereas the inset (right) shows the original design.

control over its operation. Unfortunately this only added to poor visibility afforded to the driver, which was the nearside position on BR Standards as opposed to offside on WR engines. Because of this Swindon then lowered the whole assembly, having to modify the pipework to reach the new position. When the locomotives were allocated away in 1961, Swindon removed their equipment. However, in some cases, but not all, the Exhaust Ejector was repositioned when back on LMR. Thus it was possible for a Western Region Britannias Nos 70015-70029 to be seen in all 5 different conditions, with the exception of No 70021 Morning Star, which retained its original state. For the discerning modeller, the truncated ducting of 70047 (left) has been discarded following examination whereas the inset (right) shows the original design.

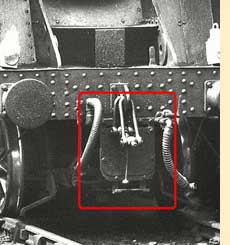

5. FRONT END REGULATOR ROD BRACKET MOD: A Regulator Rod Bracket Modification was fitted to middle of the operating rod to combat vibration, which was reported by crews, causing movement of the steamchest lever. The bracket was fitted to those already in service, Nos. 70000 to 70024. The second batch of locos Nos 70025 to 70044 were fitted from new.

6. DOME COVER MOD: At first this cover was very low indeed, and could be seen on Nos 70000 to 70006. A problem was noticed quite soon with a 'blow by' on one of the cylinders of 70000 Britannia, and this was repaired without knowing the root cause at that time. It was later found to be the Dome Cover which was too low and allowed water into the steamchest, which found its way into the cylinders.

repaired without knowing the root cause at that time. It was later found to be the Dome Cover which was too low and allowed water into the steamchest, which found its way into the cylinders.

7. REAR REGULATOR ROD SUPPORT BRACKET MOD: (Right) The support bracket was added later in life to those numbered 70000 to 70044, with the exception of Nos 70024-70044 which were constructed with the front bracket already applied to the rod. The last ten built also had the two brackets (front and rear) from new.

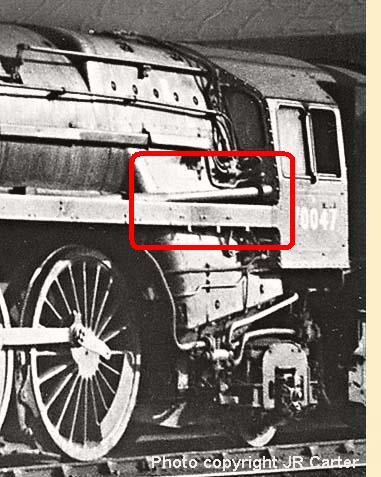

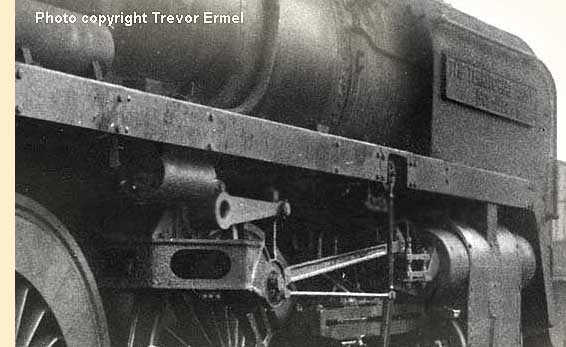

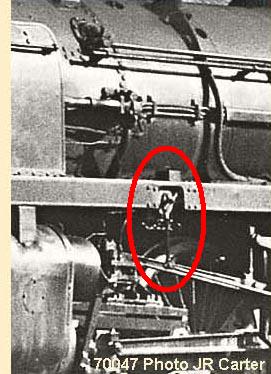

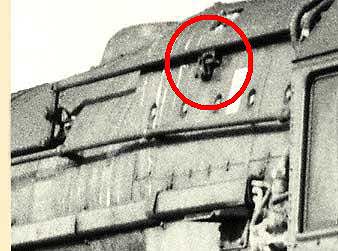

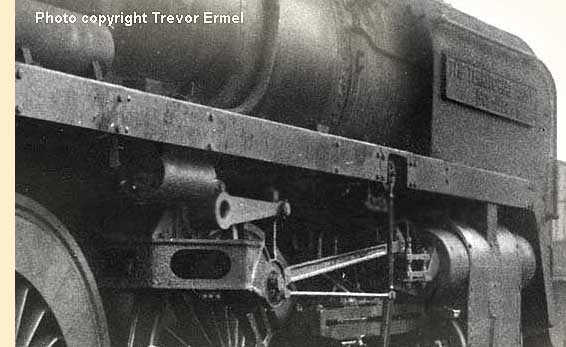

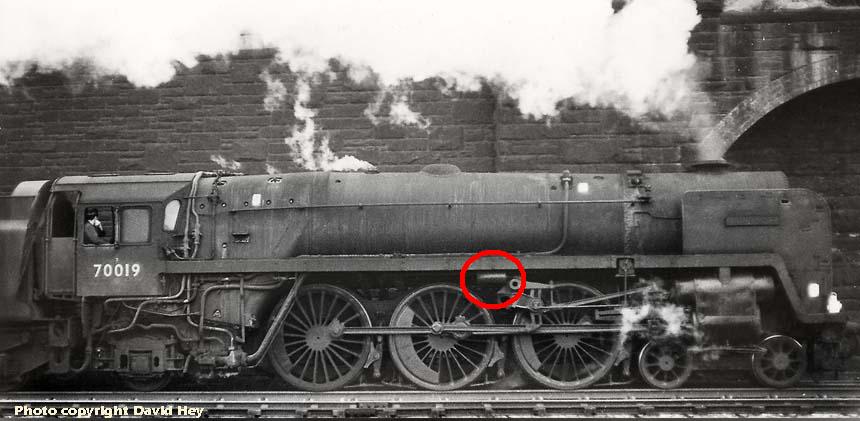

8. REVERSE ROD RETURN SPRING COVER: (Left-Below) The inset (left) of unnamed No 70047 shows the position of the reverse rod protruding from the cab on the Driver's side of the engine; this rod continued beneath the running plate to a large cast bracket which carried a cross-shaft to the other side of the loco, enabling both sets of valves to be repositioned for reversing. However, the actual Modification No 8 refers to the Reverse Rod Return Spring mounted beneath the running plate on the offside of the engine. (Right) This photo of 70048 is a good close-up of the Coupling Rod, Connecting Rod, reverse-spring housing, the associated lever and the AWS reservoir (above the walkway). Also in good view, are the cylinder and the double-lined nameplate, which was the largest of the

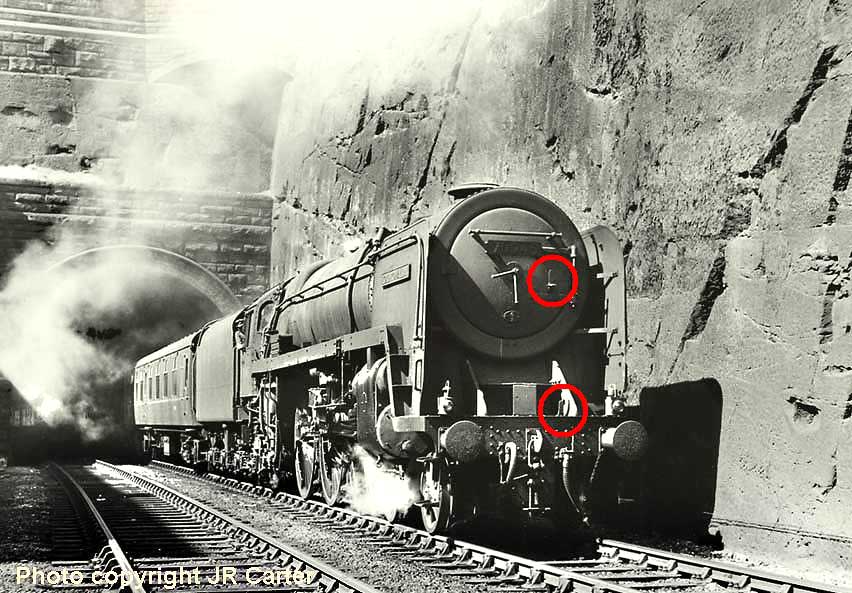

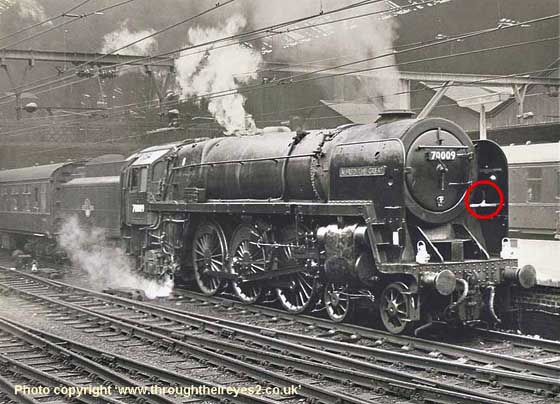

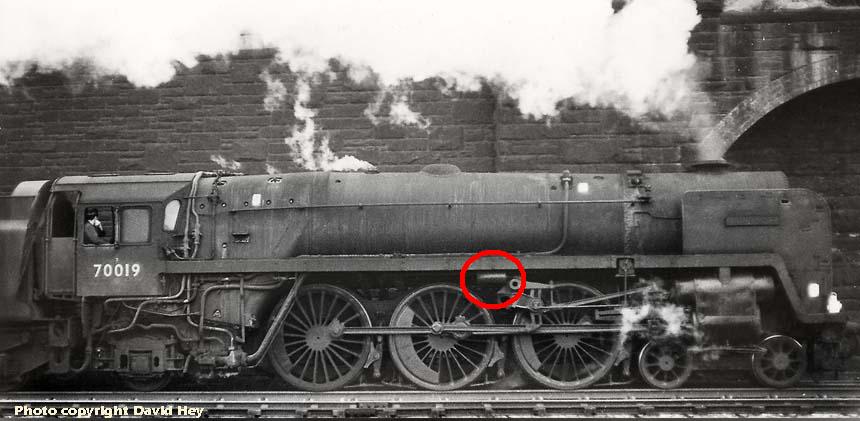

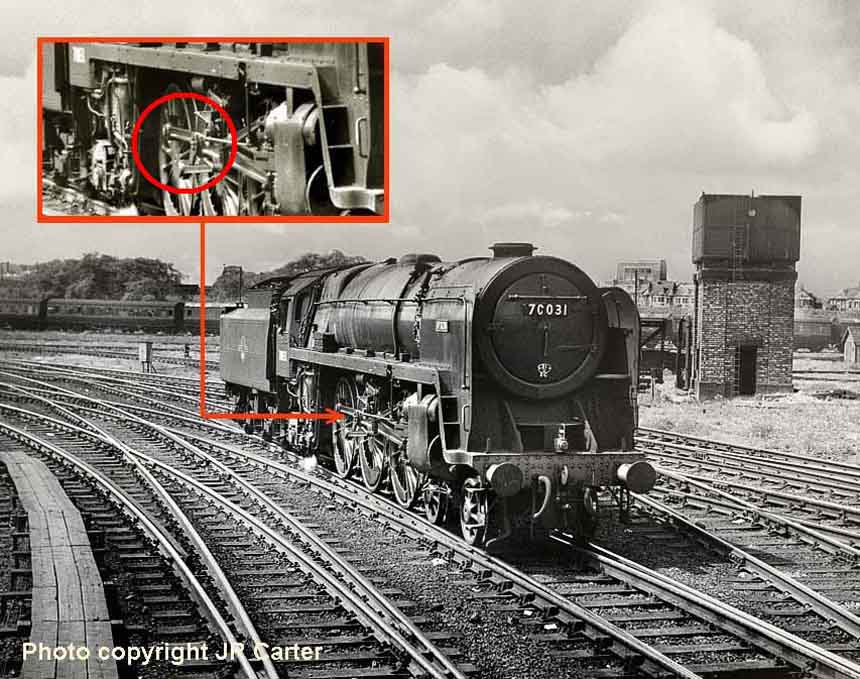

enabling both sets of valves to be repositioned for reversing. However, the actual Modification No 8 refers to the Reverse Rod Return Spring mounted beneath the running plate on the offside of the engine. (Right) This photo of 70048 is a good close-up of the Coupling Rod, Connecting Rod, reverse-spring housing, the associated lever and the AWS reservoir (above the walkway). Also in good view, are the cylinder and the double-lined nameplate, which was the largest of the  Britannias. (Below) The red circle in the photo of 70019 Lightning shows the position of the encased coil spring between the first and second drivers. This modification was carried out on all 'Britannias' after No 70010 suffered a lock-up in reverse gear in 1952.

Britannias. (Below) The red circle in the photo of 70019 Lightning shows the position of the encased coil spring between the first and second drivers. This modification was carried out on all 'Britannias' after No 70010 suffered a lock-up in reverse gear in 1952.

9. CAB SHEETS: Complaints by enginemen of cold draughts in the cab whipping up coal dust was rectified by the fitting of a flexible rubber sheet between the tender and cab. No 70023 was the first to be modified, then other crews wanted their engine done likewise, and so, of course, the rest were treated in the same way, all in the period 1952 to 1953. The deplorable state of No 70019 (below) is typica, circa 1964.

10. TENDER STEP MOD: (Above) Constructed at Crewe works, No 70021 was among the first batch (Nos 70000-70024) built between January and October 1951. ER Morten's photo is dated 6th August 1951, and judging by the pristine paintwork of both locomotive and tender it has just rolled off the production line: note the hollow axles and the bolted cover is in front of lubrication pump (they were always left off latterly) and compare the low dome on the tender, but of

10. TENDER STEP MOD: (Above) Constructed at Crewe works, No 70021 was among the first batch (Nos 70000-70024) built between January and October 1951. ER Morten's photo is dated 6th August 1951, and judging by the pristine paintwork of both locomotive and tender it has just rolled off the production line: note the hollow axles and the bolted cover is in front of lubrication pump (they were always left off latterly) and compare the low dome on the tender, but of  particular interest is the absence of a tender step. From 1953 steps were fitted to the inset-sided BR1 tender to help prevent the fireman from slipping when refilling the tender. All engines up to 70044 received these, but Nos 70045 to 70054 did not as they were coupled to the BR1D tender with no inset sides. There were two types of tender step fitted, the more common LMR Type (above left) and the less common WR type (right). (Below) This close up shot shows the tender detail of 70039 Sir Christopher Wren leaving Kings Cross on 15th June 1962.

particular interest is the absence of a tender step. From 1953 steps were fitted to the inset-sided BR1 tender to help prevent the fireman from slipping when refilling the tender. All engines up to 70044 received these, but Nos 70045 to 70054 did not as they were coupled to the BR1D tender with no inset sides. There were two types of tender step fitted, the more common LMR Type (above left) and the less common WR type (right). (Below) This close up shot shows the tender detail of 70039 Sir Christopher Wren leaving Kings Cross on 15th June 1962.

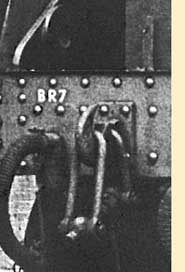

11. BR TOTEM: (Inset-Below) Upon nationalisation in 1948, the first British Railways totem consisted of a 'British Lion' astride a flanged wheel to symbolize rail transport. This was followed by a second totem which had the 'British Lion' rising from a crown holding a driving wheel in its front paws. The reason a lion is commonly used in heraldry is because it traditionally symbolises bravery, valour, strength and royalty. However, when the new BR emblem was applied, the 'rampant lion' - this describes a heraldic lion standing on its hind legs - was reversed on the right hand (offside) so that it faced the front of the locomotive. This seemed a logical deduction except that it contradicted the strict Heraldic Rules laid down in 1947 which states that the lion should face to the left. The mistake was seen on many locomotives on all Regions before it was noticed and the offside emblems were substituted with the correct ones. The incorrect emblem can be seen on the tender of 70026 Polar Star (below). The new BR emblem was first applied to No 70016 Ariel in July 1956, and 70004 William Shakespeare was the last of the class to be in receipt of the update in April 1964. An unusual smaller size was applied to 70003 - unusual because this would normally have been used on smaller tank engines.

had the 'British Lion' rising from a crown holding a driving wheel in its front paws. The reason a lion is commonly used in heraldry is because it traditionally symbolises bravery, valour, strength and royalty. However, when the new BR emblem was applied, the 'rampant lion' - this describes a heraldic lion standing on its hind legs - was reversed on the right hand (offside) so that it faced the front of the locomotive. This seemed a logical deduction except that it contradicted the strict Heraldic Rules laid down in 1947 which states that the lion should face to the left. The mistake was seen on many locomotives on all Regions before it was noticed and the offside emblems were substituted with the correct ones. The incorrect emblem can be seen on the tender of 70026 Polar Star (below). The new BR emblem was first applied to No 70016 Ariel in July 1956, and 70004 William Shakespeare was the last of the class to be in receipt of the update in April 1964. An unusual smaller size was applied to 70003 - unusual because this would normally have been used on smaller tank engines.

(Below) A good ¾ rear view of the BR1D tender as used by the last ten locos in the Britannia Class, in this case 70052 Firth of Tay; the loco is being piloted a Stanier 2-6-4T on a Manchester-Glasgow train at Salford. The raking light affords a good view of the later BR emblem, the LMSR Return Crank with 4 studs and the Speedometer which was fitted from new on the last ten engines. Also of note is the class identification '7P' just visible above the cabside number; this applied from 1961 and only appeared on 5 locos: 70017, 70042, 70046, 70048 and 70052. The smoke deflectors were not changed on this engine, being one of sixteen of the class not altered in this respect. The BR1D tenders were larger and heavier than the earlier BR1 type with inset sides. The BR1D had a capacity of 9 tons of coal and 4,725 gallons of water, and were also equipped with a steam operated coal pusher to aid the fireman.

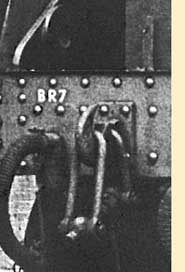

12. LIVERY: Several changes were made throughout their careers including Full Lining, Part Lining and

12. LIVERY: Several changes were made throughout their careers including Full Lining, Part Lining and  even no lining at all, along with 'BR 7' on the front buffer beam and either '7' or '7P' or '7P6F' denoting the loco's power classification applied to the cabside. Other slight differences were the various colour backing for the nameplates, which were red, black or blue. Five engines were seen in 1961 showing '7P' on the cab, whereas '7P 6F' was only seen on 70004 for a very short time during 1954.

even no lining at all, along with 'BR 7' on the front buffer beam and either '7' or '7P' or '7P6F' denoting the loco's power classification applied to the cabside. Other slight differences were the various colour backing for the nameplates, which were red, black or blue. Five engines were seen in 1961 showing '7P' on the cab, whereas '7P 6F' was only seen on 70004 for a very short time during 1954.

13. SPEEDOMETER: The speedometer (right) was fitted to the nearside rear drive wheel centre via a short plate; the first one to be applied in service was No 70044 in July 1955, and the last being No 70017 in July 1962. However, 12 engines did not have one fitted, whereas the last 10 locos in the class Nos 70045-54 were built with them on.

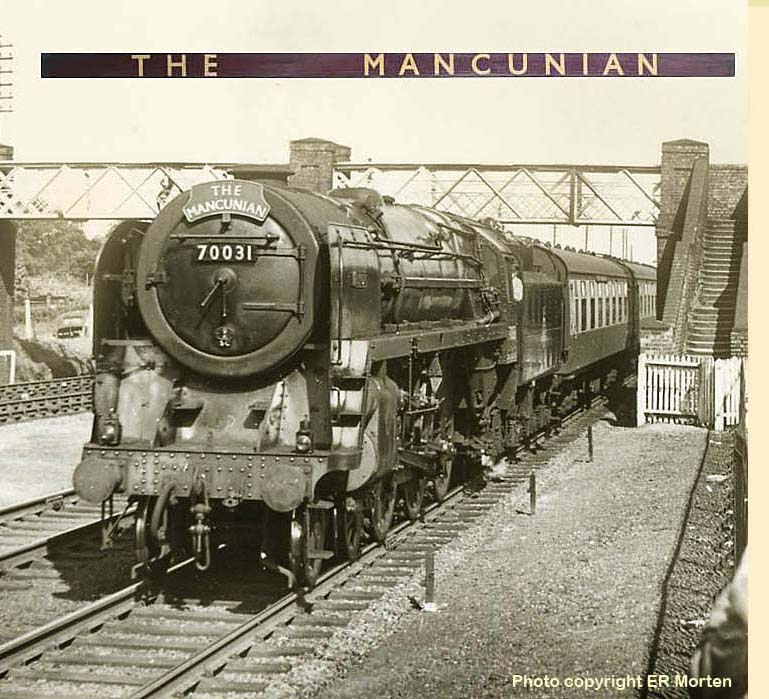

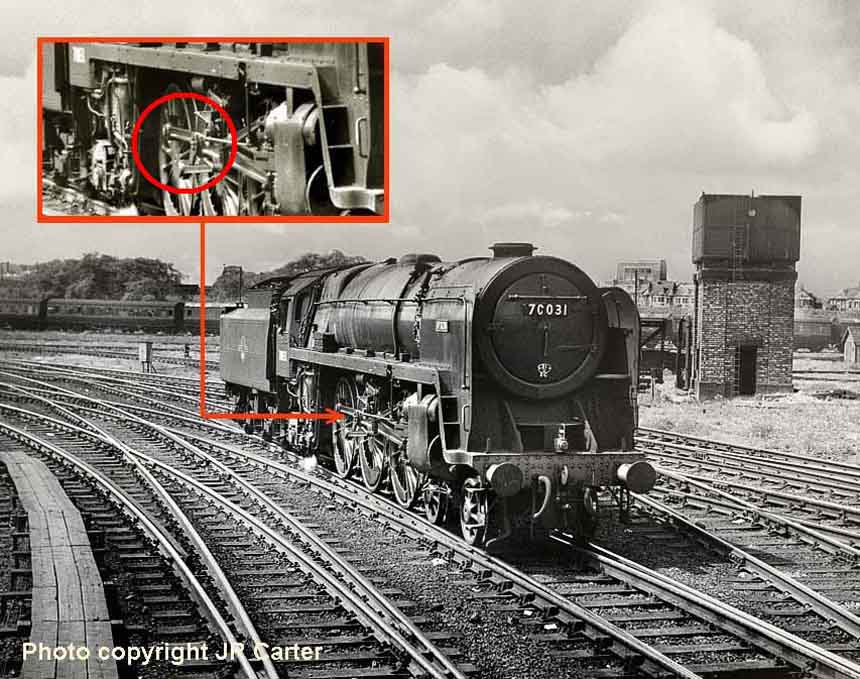

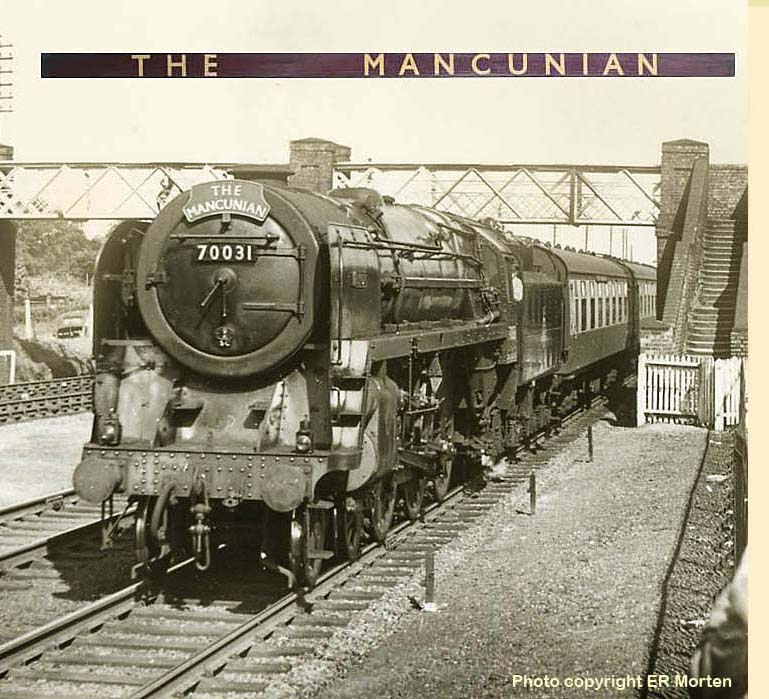

14. COUPLING RODS: The coupling rods were originally designed to be fluted (ie lighter) but following serious breakdowns caused by 'wheel shift' early in life (see Axle Modification below) the decision was made to replace the fluted rod with a plain-type rod, albeit they were more weighty. However a problem occurred when insufficient new parts could be found, and so many engines had a plain rod at the front, but a fluted variety to the rear. Nos 70004/70014 were seen throughout their careers with a 'mix of rods'. (Above) Following operating experience with the first batch of 'Britannias Nos 70000-70024, the second batch to emerge from Crewe (Nos 70025-70044) now incorporated many of the modifications deemed necessary on the first group. Introduced to traffic on 29th November 1952, 70031 Byron was among four 'Britannias' allocated to Holyhead (70030, 70032 & 70033 being the others) for use on the London Euston-Holyhead runs, but after a short while in service it was found that the BR1 tender's inadequate water and coal capacities (7 tons of coal and 4725 gallons of water) made them unsuitable for long distance running between Euston and Holyhead.

emerge from Crewe (Nos 70025-70044) now incorporated many of the modifications deemed necessary on the first group. Introduced to traffic on 29th November 1952, 70031 Byron was among four 'Britannias' allocated to Holyhead (70030, 70032 & 70033 being the others) for use on the London Euston-Holyhead runs, but after a short while in service it was found that the BR1 tender's inadequate water and coal capacities (7 tons of coal and 4725 gallons of water) made them unsuitable for long distance running between Euston and Holyhead.

(Left) After only a month in North Wales the BR7s were transferred to Longsight and 70031 was frequently employed on the Manchester-London Euston 'Mancunian'. Here 70031 Byron heads the southbound 'Mancunian' at Madeley on 3rd August 1953. The onset of Type 4 Sulzer diesels on WCML duties led to the 'Britannias' being ousted and 70031 was transferred to Aston (21D) followed by spells at Willesden, Crewe and Carlisle before being finally withdrawn from Kingmoor on 11th November 1967; 70031 was cut up at McWilliams of Shettleston in March 1968.

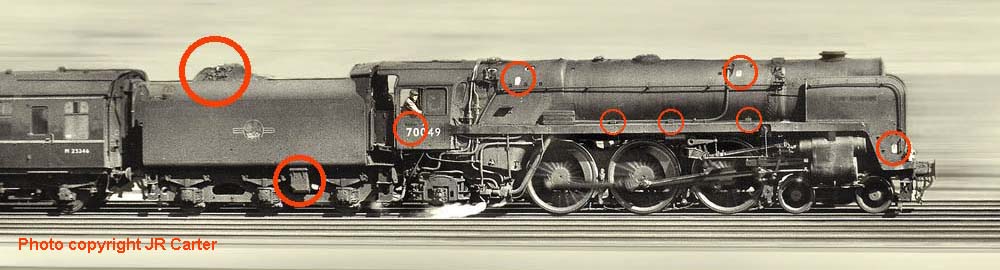

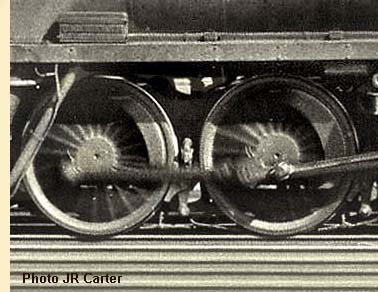

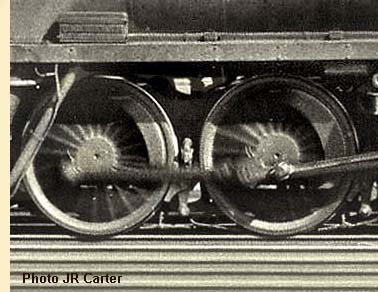

(Below) This fantastic close up shot by 'Footplate Cameraman' Jim Carter, highlights the large wheels, plain coupling rods, LMSR Return Crank, three sand box lids, original smoke deflectors and both support brackets for the regulator rods are clearly seen. The loco was fitted with a speedometer when new, but this has now been removed, leaving behind the angled bracket on the rear driving wheel. No 70047 was the only unnamed engine of the class, but 'Lancashire & Yorkshire' had been proposed. A full image of this shot of 'Britannia' Class 7MT No 70047 and 'Scot' class 46127 Old Contemptibles at Crewe South shed (5B) can be found here on Chris Carter's dedication to his dad on Page 64.

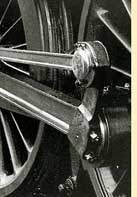

15. LNER RETURN CRANK: (Left-Right) This was part of Doncaster's contribution to the class. A few engines kept these throughout their lives, but others were found to crack, these being modified to LMSR Return Crank, with a 4-pin fixing. Nos. 70001, 70002, 70011, 70025, 70030 and 70034 were some of those not altered, whereas Nos. 70003 & 70012 were changed to LMSR type and then reverted to original design. The insert (right) gives a decent view of the LMSR Return Crank, a 4-pin fixing as opposed to the original twin cotter pins (left).

15. LNER RETURN CRANK: (Left-Right) This was part of Doncaster's contribution to the class. A few engines kept these throughout their lives, but others were found to crack, these being modified to LMSR Return Crank, with a 4-pin fixing. Nos. 70001, 70002, 70011, 70025, 70030 and 70034 were some of those not altered, whereas Nos. 70003 & 70012 were changed to LMSR type and then reverted to original design. The insert (right) gives a decent view of the LMSR Return Crank, a 4-pin fixing as opposed to the original twin cotter pins (left).

16. SAND BOX LID: the first batch of engines had two sand boxes fitted level flush with the boiler walkway on each side of the loco. All was fine until 70024 slipped to a standstill on wet rails during an early morning turn in the Plymouth area. It was found that the sanders were not actually working and so a decision was taken to remove the steam coils; this work was carried out from 1953 onwards. Also from 70030 to 70054, an additional sand box was fitted level with the front of the leading drive axle on each side. These sand boxes had raised lids to aid filling; at the same time a number of engines already in service - No 70004, and Nos 70014 to 70024 - were modified likewise at Swindon Works. Meanwhile Nos 70025 to 70029 were equipped with two raised sand boxes from new; No 70027 even had a special modified surround to the filler lids until about 1958. The system was devised by William Downs, Foreman at West Auckland shed, though it was thought that the type of sand used on the WR was not very suitable for the purpose.

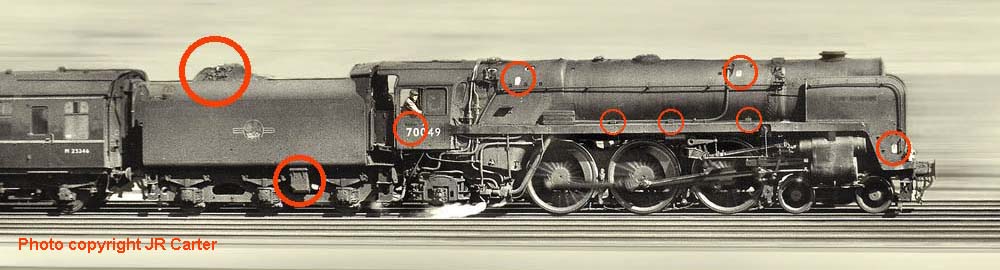

(Above) The pipe run supplying the two sand boxes on the earlier types was found to be very restrictive, hence 70030-70054 emerged from Crewe Works with an additional sand box situated in a forward position level with the front of the leading drive axle on each side; this delivered a more efficient sanding operation. The clarity of Jim Carter's panning shot of 70049 at Winwick Junction shows the 3 raised sand box lids (the additional sand box is shown left) plus several other detailed differences. Note the three power flashes and removal of the nameplate as a

hence 70030-70054 emerged from Crewe Works with an additional sand box situated in a forward position level with the front of the leading drive axle on each side; this delivered a more efficient sanding operation. The clarity of Jim Carter's panning shot of 70049 at Winwick Junction shows the 3 raised sand box lids (the additional sand box is shown left) plus several other detailed differences. Note the three power flashes and removal of the nameplate as a  precautionary measure against theft; the AWS battery box can be seen above the rear driving wheel and the sludge collector at the bottom of tender between first two axles plus the steam-operated coal pusher atop the tender at the rear. Of particular interest is the bracket above the cabside number (right) a legacy of someone's brainwave to have the driver's name attached to cab side...needless to say, this went down like the proverbial lead balloon! The plain coupling rods were fitted from new after incidencies of 'wheel shifting' (described in 17. Axle Modification below) but there was little in the way of 'standardisation' since several members of the class were seen with a 'mix of rods', having plain rods at the front and the fluted variety towards the cab.

precautionary measure against theft; the AWS battery box can be seen above the rear driving wheel and the sludge collector at the bottom of tender between first two axles plus the steam-operated coal pusher atop the tender at the rear. Of particular interest is the bracket above the cabside number (right) a legacy of someone's brainwave to have the driver's name attached to cab side...needless to say, this went down like the proverbial lead balloon! The plain coupling rods were fitted from new after incidencies of 'wheel shifting' (described in 17. Axle Modification below) but there was little in the way of 'standardisation' since several members of the class were seen with a 'mix of rods', having plain rods at the front and the fluted variety towards the cab.

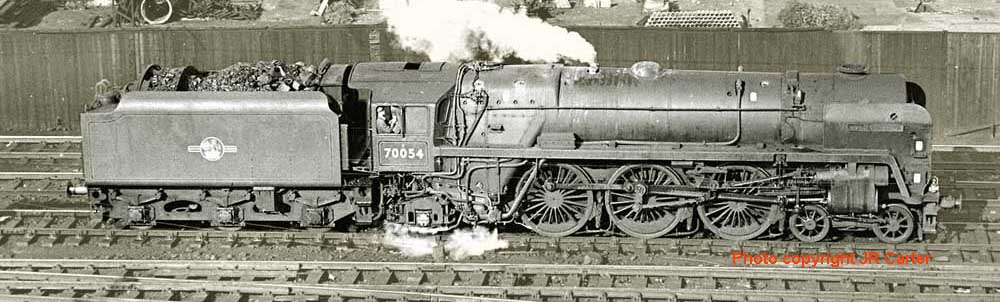

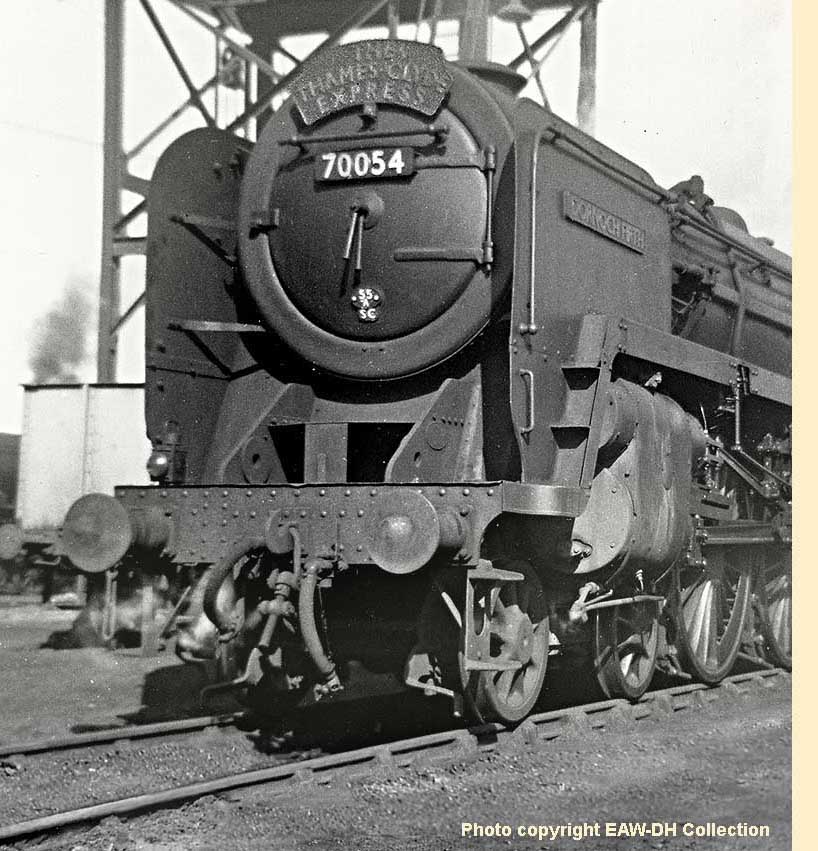

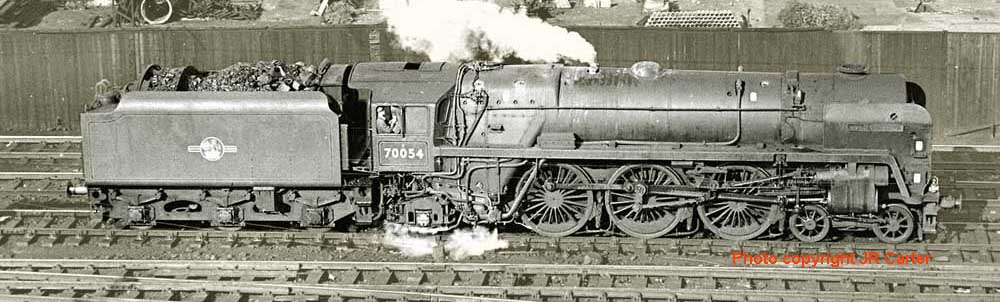

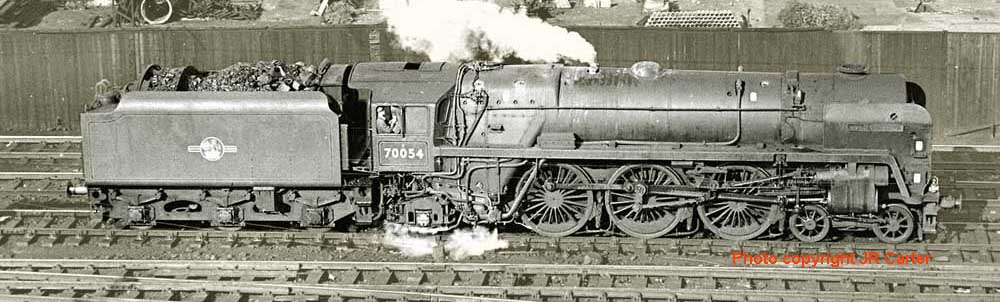

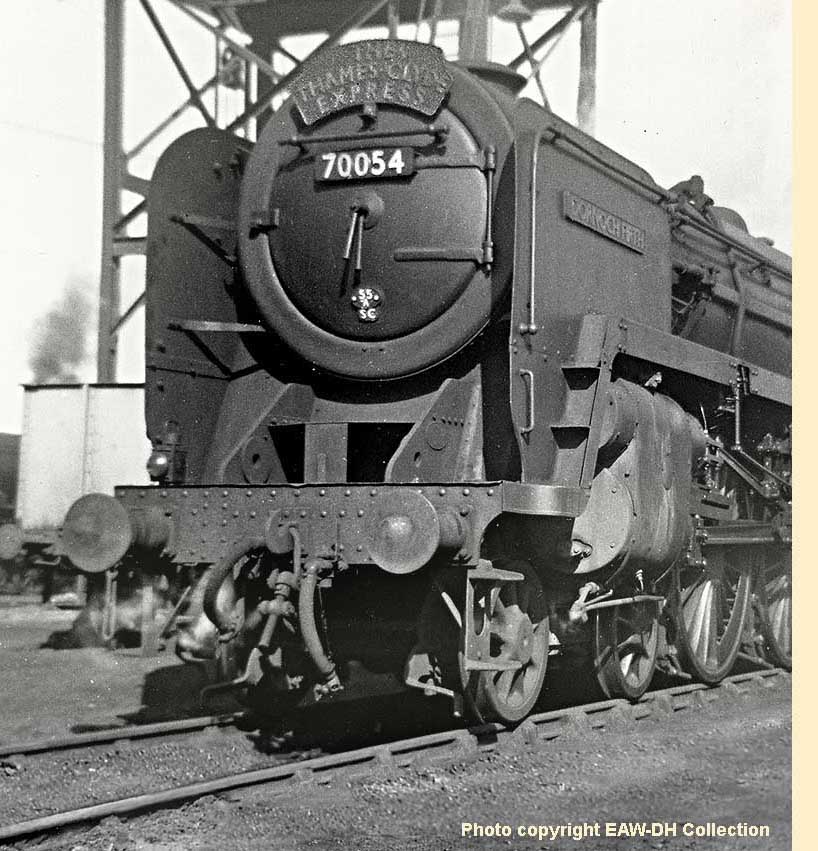

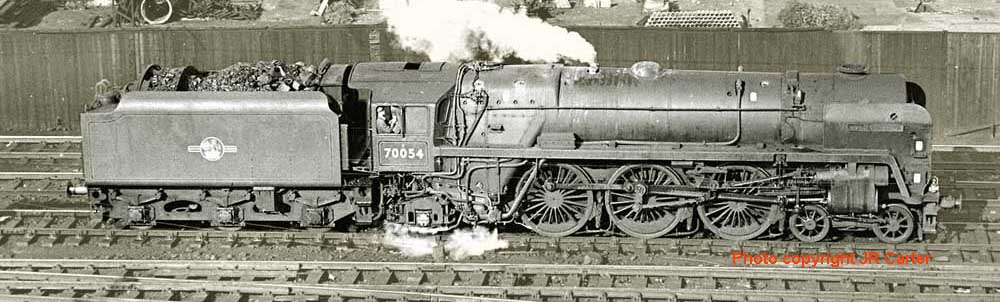

(Left-Below) Although there were plans to build a further thirty five 'Britannias', 70054 Dornoch Firth was the last of the class to be built at a cost of £25,331 - £5,006 more than the cost of 70000 three and half years earlier. 70054 went into service on 13th September 1954, allocated initially to Polmadie for 4 years, then to Leeds Holbeck for another 4 years. 70054 was often employed on Glasgow-Liverpool and Glasgow- Birmingham trains, and during its spell at Holbeck 55A (left), the 'Thames-Clyde' and 'Waverley' express were regular turns. 70054 was coupled to a larger BR1D tender, holding 4,725 gallons of water and 9 tons of coal, with a steam operated coal pusher to aid the fireman. 70054 was also allocated to Banbury mpd, along with 70046, 70047, 70049, 70050, 70051, & 70052, dated late 1965, certainly a rather unspectacular career, for such a large engine.

(Left-Below) Although there were plans to build a further thirty five 'Britannias', 70054 Dornoch Firth was the last of the class to be built at a cost of £25,331 - £5,006 more than the cost of 70000 three and half years earlier. 70054 went into service on 13th September 1954, allocated initially to Polmadie for 4 years, then to Leeds Holbeck for another 4 years. 70054 was often employed on Glasgow-Liverpool and Glasgow- Birmingham trains, and during its spell at Holbeck 55A (left), the 'Thames-Clyde' and 'Waverley' express were regular turns. 70054 was coupled to a larger BR1D tender, holding 4,725 gallons of water and 9 tons of coal, with a steam operated coal pusher to aid the fireman. 70054 was also allocated to Banbury mpd, along with 70046, 70047, 70049, 70050, 70051, & 70052, dated late 1965, certainly a rather unspectacular career, for such a large engine.

17. AXLE MOD: The axle modifications had to be carried out on the first 25 Locos Nos 70000 to 70024, seven members having failed in service, including 70004 on the 'Golden Arrow' at Headcorn. This was caused by drastic 'wheel shift' with ensuing breakages of the Coupling Rods; the root cause being the hollow axles designed to save weight. It should be noted that in 1948 four Black Fives suffered 'wheel shift' but they were repaired and had no problem thereafter; also the Coronation class, the GWR Kings and the 9Fs had hollow axles with no similar problems. Although No 70000 was not affected by 'wheel shift' the loco was laid up until modifications could be made at Crewe Works in late 1951. It was deemed fortunate that construction of the second batch had not yet begun, but this was purely down to an acute shortage of steel from October 1951. Construction didn't restart until almost twelve months later with No 70025 Western Star destined for the Western Region. It is worth noting that within a few months at the start of 1951, the Britannia class was seen at Liverpool Street (70000 of course being the first), at Marylebone (70000 & 70004), at Waterloo (70009, 70014 followed by 70004), then at Paddington (70017 being the first) and at Euston where 70015 arrived at the head of 'The Comet' in June 1951. The following year No 70000 was observed hauling the Royal Train from Sandringham to King's Cross in February 1952, thus completing an appearance by the class at the 'full set' of London termini as it were...(below) 70038 Robin Hood departs Kings Cross with a train for Boston Lincolnshire.

shift' but they were repaired and had no problem thereafter; also the Coronation class, the GWR Kings and the 9Fs had hollow axles with no similar problems. Although No 70000 was not affected by 'wheel shift' the loco was laid up until modifications could be made at Crewe Works in late 1951. It was deemed fortunate that construction of the second batch had not yet begun, but this was purely down to an acute shortage of steel from October 1951. Construction didn't restart until almost twelve months later with No 70025 Western Star destined for the Western Region. It is worth noting that within a few months at the start of 1951, the Britannia class was seen at Liverpool Street (70000 of course being the first), at Marylebone (70000 & 70004), at Waterloo (70009, 70014 followed by 70004), then at Paddington (70017 being the first) and at Euston where 70015 arrived at the head of 'The Comet' in June 1951. The following year No 70000 was observed hauling the Royal Train from Sandringham to King's Cross in February 1952, thus completing an appearance by the class at the 'full set' of London termini as it were...(below) 70038 Robin Hood departs Kings Cross with a train for Boston Lincolnshire.

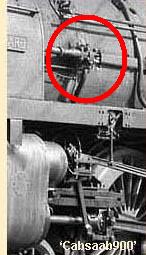

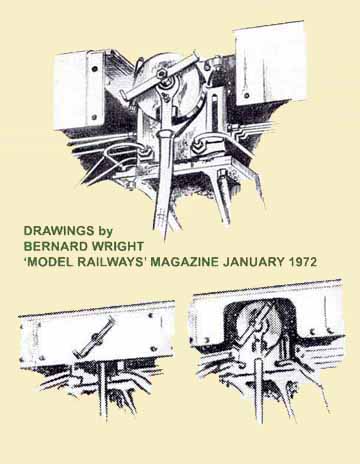

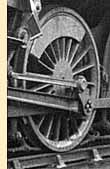

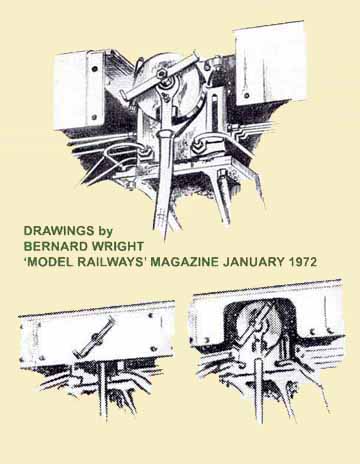

18. LUBRICATION OPERATING ROD: (Above-Right) This rod is highly visible being just above the front drive wheels (circled right) and in the first instance is in a horizontal position and at a right-angle to the pump lever, but if more lubrication is

18. LUBRICATION OPERATING ROD: (Above-Right) This rod is highly visible being just above the front drive wheels (circled right) and in the first instance is in a horizontal position and at a right-angle to the pump lever, but if more lubrication is  required, the lever rod is shortened to give a slightly higher rate of delivery. These units were designed by Swindon Drawing office to feed atomised oil to the cylinders and valves, and are fitted to the Britannia class, tucked away under the running board (boiler walkway).

required, the lever rod is shortened to give a slightly higher rate of delivery. These units were designed by Swindon Drawing office to feed atomised oil to the cylinders and valves, and are fitted to the Britannia class, tucked away under the running board (boiler walkway).

19. POWER WARNING FLASHES: The Power Warning flashes were applied to almost all engines throughout the Regions during 1961-1962 to remind crews of the danger of working in the vicinity of the overhead wires; as a further precaution the lamp irons were repositioned so that the crew did not have to stretch towards the live wires. The warning flashes were often fitted at sheds, therefore they were rather randomly positioned and differed in the numbers fitted; some engines displayed 2 to 3 flashes, but more often 4 were applied, and even 5 each side appeared on some engines. They were also applied to the tender, this being one of the most dangerous areas for the engine crew when required to climb on top of the tender to add water or move the coal forward.

20. ATC/AWS MOD: The Automatic Warning System speaks for itself, and was fitted by Doncaster works during September 1959. However many of the class did not receive either ATC or AWS, yet some engines were fitted with both systems - ATC whilst working on the GWR, then AWS when allocated to LMSR. The on-track sensors alerted the train mechanism in the cab via magnets, and this warned the driver of adverse signals ahead by way of an audible warning. If the driver did not respond the brakes were automatically applied. The Crewe-fitted ATC system (invented in 1906) was added to the GW section engines as built, with the battery box situated under the nearside cab, and no other engines were so treated. The later BR version (AWS) was fitted to many, but not all, engines from 1959. Indeed some locos used

The on-track sensors alerted the train mechanism in the cab via magnets, and this warned the driver of adverse signals ahead by way of an audible warning. If the driver did not respond the brakes were automatically applied. The Crewe-fitted ATC system (invented in 1906) was added to the GW section engines as built, with the battery box situated under the nearside cab, and no other engines were so treated. The later BR version (AWS) was fitted to many, but not all, engines from 1959. Indeed some locos used  both systems, some had one or the other, and two engines Nos 70004 and 70042 had neither. (Left) Close-up of the protector plate for the AWS unit behind, this one fitted to 70013.

both systems, some had one or the other, and two engines Nos 70004 and 70042 had neither. (Left) Close-up of the protector plate for the AWS unit behind, this one fitted to 70013.

(Below) 70025 Western Star takes the Manchester line out of Chester with a short container wagon load. This ex-WR engine was fitted with AWS (Automatic Warning System) as late as December 1962, so this photo by Jim Carter would be from 1963. 70025 was the first of the second batch to be built, thus it was modified in many ways compared to the initial Locomotives of the class: this included axles, raised dome cover, shorter vacuum pie, support bracket on the regulator front rod, and the two raised sand box lids either side are now standard. But 70025 did not go to Cardiff Canton as anticipated, she went to Rugby Testing Station instead for steaming and fuel consumption tests. Her best work was done on the South Wales expresses from May 1953 to September 1961, being transferred to Aston in the Birmingham area, then onto Crewe, Llandudno and Carlisle. Of note are the fitments on the offside running plate which are the Battery Box (for AWS) and the round vacuum reservoir, just in front of it.

21. VACUUM PIPE: The vacuum pipe in their original form was a tall standpipe and these were only fitted to Nos 70000-70018 inclusive, then all other production engines were given the modified much-shorter version. Therefore with regard to identification, a 'Britannia' class with the tall pipe reveals the date of construction as being no later than 1953.

(Below) We finish this page with the late David Champion's splendid photo of Class 7MT No 70000 Britannia storming away from Woking with driver, Pat Kinsella at the controls on Sunday 8th May 1994; Pat Kinsella writes - 'This was the first Mid-Hants Daylight steam special over LSWR metals for 27 years. At that time 70000 had a steam brake on both engine and tender, and was vacuum fitted for train braking; compressor and air braking was fitted much later for air-braked trains.

As I had never driven a BR Standard Pacific before, I enquired of one of the maintenance support crew before we started away from London Waterloo - 'Where is the best place to work the lever?'

'Forty five and all the regulator,' he replied seriously, 'She'll fly!'

Good grief! I thought to myself, she'll take off!...but of course it wasn't necessary to trash this wonderful locomotive, if I had, my fireman, Den Osman would have probably downed tools! We burned enough coal as it was! Dave Champion's photo shows my inspector, Bill James, standing behind me, leaning on the cab door...'

CLICK ON NEXT PAGE FOR AN IN-DEPTH STUDY OF BRITANNIA CLASS Nos 70000-70024

The Class 7MT Pacific was the first of twelve new 'standard' classes, however the full complement of fifty five locomotives Nos 70000-70054 were far from 'standard'. I havebeen contacted by the eagle-eyed Derek Dean, who describes 14 visible modifications of No 70000 in the above two photos at York alone!

Now I ask you…who would have thought it?

This is worth further investigation, I thought and so I am indebted to Derek Dean for submitting an article on the subject. He writes - 'David, if you believe that a detailed explanation of the quoted modifications will be of interest to enthusiasts in general, and to railway modellers especially, then that's what we shall do...'

CHANGING STANDARDS

by Derek Dean

Designed at Derby and built at Crewe, with additional sections designed at Brighton, Doncaster and Swindon, the basic ethos of the new BR Class 7MT 'Britannia' Pacific was simplicity in construction, lower coal consumption, and longer mileage between classified repairs. The Class 7MT was a straightforward 2-cylinder design, and probably more of an amalgam of the former 'Big Four' companies engines than any other Standard class. The boiler, cylinders and valve gear came from LMS practice, the main frame and trailing truck from the Southern Railway, and the crossheads and slidebars were influenced by the LNER, whilst the GWR inspired the mechanical lubrication and various other steam fittings.

The name 'Britannia' was thought of by Rev Eric Treacy, but the engine was nameless when first seen in black livery during a period of initial testing on January 2nd 1951. The design of the engine was attained by a team of eight men led by RA Riddles, RC Bond and ES Cox, all three being ex-LMR men...hence it came as no surprise that a decision was taken to build the new BR Standard Pacific at Crewe Works.

The design was augmented by using other Regional Drawing Offices at Derby, Brighton, Swindon and Doncaster, each having some input and involvement in the completed design. The locomotives were expected to have a life-span of 40 years, whereas in reality, the class only had a really useful span of 10 years in service and would no doubt have been banished some way before 1967, but for the fact of the cost

of the class.

of the class.The design is generally accredited to Robin Riddles, but the main mechanical ideas came from ES Cox, although he did not succeed in his wish to build the locomotives with bar frames. These would have been much stronger than the frames used, which were of 1.25 in plate and horizontal rack stays, this being due to the fact that Britain's Locomotive Works weren't equipped to build such engines.

The boilers were based on the 'Coronation' class Pacifics and the angle of the sloping fronts 67 degrees, a figure decided upon by Air Dynamic Tests. After successful tests, 'Britannia' returned to Crewe Works for final adjustments and after a repaint in the chosen Brunswick Green livery, the nameplates were fitted.

(Above Right-Below) The doyen of the class, No 70000 Britannia, was photographed by Railway Cameraman Keith Long on the service line at London Liverpool Street station on 30th August 1960. Following the

introduction of the BR Standard Class 7MT locomotives to traffic, several modifications were made to improve their performance, many of which were clearly visible, others less so - therefore for the benefit of younger modellers a list of the detailed alterations are featured in a numbered sequence below. However it would be wrong to describe them all as modifications, more like additions-improvements, such as the fitting of cab sheets, but they are included here to help the discerning modeller, artist and model engineer replicate a particular period during the class's career between 1951-1968. (Below) A most magnificent live steam 3½" Gauge Locomotive 70000 Britannia, built to the highest possible standard with immaculate detail to challenge the best show model of its class. This superb model (including a glass display case) went under the hammer for £7,000 at a Great Western Railwayana Auction in May 2012...a step-by-step analysis of the various modifications of the BR Class 7 Pacific can be found further down the page..

introduction of the BR Standard Class 7MT locomotives to traffic, several modifications were made to improve their performance, many of which were clearly visible, others less so - therefore for the benefit of younger modellers a list of the detailed alterations are featured in a numbered sequence below. However it would be wrong to describe them all as modifications, more like additions-improvements, such as the fitting of cab sheets, but they are included here to help the discerning modeller, artist and model engineer replicate a particular period during the class's career between 1951-1968. (Below) A most magnificent live steam 3½" Gauge Locomotive 70000 Britannia, built to the highest possible standard with immaculate detail to challenge the best show model of its class. This superb model (including a glass display case) went under the hammer for £7,000 at a Great Western Railwayana Auction in May 2012...a step-by-step analysis of the various modifications of the BR Class 7 Pacific can be found further down the page..

(Above) 1. FRONT STEP; 2. LAMP IRONS; 3. SMOKE DEFLECTORS; 4. EXHAUST EJECTOR MOD; 5. FRONT REGULATOR ROD SUPPORT BRACKET; 6. DOME COVER; 7. REAR REGULATOR ROD SUPPORT BRACKET; 8. REVERSE ROD RETURN SPRING COVER; 9. CAB SHEET MOD; 10.TENDER STEP; 11.NEW BR TOTEM; 12.LIVERY; 13.SPEEDOMETER; 14.COUPLING RODS; 15.LNER-LMSR RETURN CRANK; 16.SANDBOX LIDS; 17.AXLE; 18.LUBRICATION PUMP OPERATING ROD; 19.POWER WARNING FLASHES; 20.ATC/AWS and 21.VACUUM PIPE.

(Below) In all fairness to 'Rail Camerman' Keith Long, here is the original photo of 'Britannia' Class 7MT No 70004 William Shakespeare at Willesden shed on 16th September 1961. Built at Crewe Works and delivered in March 1951, 70004 was exhibited at the Festival of Britain, then allocated to Stewarts Lane until 1958; she worked the 'Golden Arrow' on a regular basis and continued to carry the fixing bolt holes for the ornamental arrow in her smoke deflectors until early in 1965 when accident damage to the offside smoke deflector meant that a new sheet and stays were fitted at Darlington Works. After leaving the SR she spent time at Trafford Park, Willesden, Crewe North and Stockport until been allocated to her final shed at Kingmoor in 1967. Withdrawn in December 1967 she was scrapped at TW Ward of Inverkeithing in April 1968...check out Keith Long's superb 'Rail Camerman' Page 47 on the left-hand menu.

1. FRONT STEP MOD: The locomotives on the GE section bore many headboards on a daily basis, such as the 'Norfolkman' and 'East Anglian' etc. However, in the original design only two separate footsteps were provided beneath the smokebox door (see inset left) and engine crews had difficulty in reaching the topmost lamp iron to locate the headboards. Stratford Loco devised a simplified platform supported by a single bracket, which can be seen in the shot (above) of Britannia class No 70034 Thomas Hardy arriving at Liverpool Street with the 'East Anglian'. Built at Crewe to Order E483/228, 70034 entered service at Longsight in December 1952, but was soon transferred to the Eastern Region to

1. FRONT STEP MOD: The locomotives on the GE section bore many headboards on a daily basis, such as the 'Norfolkman' and 'East Anglian' etc. However, in the original design only two separate footsteps were provided beneath the smokebox door (see inset left) and engine crews had difficulty in reaching the topmost lamp iron to locate the headboards. Stratford Loco devised a simplified platform supported by a single bracket, which can be seen in the shot (above) of Britannia class No 70034 Thomas Hardy arriving at Liverpool Street with the 'East Anglian'. Built at Crewe to Order E483/228, 70034 entered service at Longsight in December 1952, but was soon transferred to the Eastern Region to  join the stud of 'Britannias' based at Norwich (32A) for Great Eastern main line services. It was transferred back to the LMR again in March 1963, and following withdrawal from Kingmoor in May 1967 was broken up by J McWilliam, Shettleston in October that year. (Below) Stratford's support bracket can be seen in this photo of 70003 John Bunyan heading a down Norwich express through Manningtree on 18th April 1954. This modification appeared around 1953-1954 and sufficed until Crewe Works devised a stronger, deeper version with a larger bracket. No 70000 was fitted with this full modification (right) at Doncaster Loco during December 1956. This modification superseded both the original and the Stratford type on all members of the class.

join the stud of 'Britannias' based at Norwich (32A) for Great Eastern main line services. It was transferred back to the LMR again in March 1963, and following withdrawal from Kingmoor in May 1967 was broken up by J McWilliam, Shettleston in October that year. (Below) Stratford's support bracket can be seen in this photo of 70003 John Bunyan heading a down Norwich express through Manningtree on 18th April 1954. This modification appeared around 1953-1954 and sufficed until Crewe Works devised a stronger, deeper version with a larger bracket. No 70000 was fitted with this full modification (right) at Doncaster Loco during December 1956. This modification superseded both the original and the Stratford type on all members of the class.

2.LAMP IRON MOD. Lamp Irons have always been an integral part of locomotive operating practice, but probably not much noticed by enthusiasts, so lets have a closer look at those on the Britannia Class.

I have broken these down into six different categories: 1. LMR Irons - generally 4 inches long; 2. GER Irons - generally 6 inches long enabling the white disc to be used; 3. GWR Irons - quite obviously different in size and shape; 4. SR Irons - the type referred to were made to fit on the smoke deflector stay; 5. Long Irons - seen on early SR Locos, and only on 70004/70014 and finally 6. Repositioned Irons - all engines modified.

LMR Lamp Irons were fitted to new engines until about May 1951 when the longer GER section irons were adopted on Nos 70000-70014. The LMR type was then applied to Nos 70031, 70032 & 70033, which were the only true LMR engines, and then from 70042 onwards up to the last members of the Class, including those numbered 70050 to 70054 all of which were allocated in Scotland…all engines would eventually have used these irons.

GER Lamp Irons had to be swopped with the initial LMR type on Nos 70000 to 70009, thereafter Crewe Works were building the engines with them already fitted. Twenty three locos worked on the GE section, the full list comprised of 70000, 70001, 70002, 70003, 70005, 70006, 70007, 70008, 70009, 70010, 70011, 70012, 70013, 70030, 70034, 70035, 70036, 70037, 70038, 70039, 70040, 70041 & 70042, this list does not include 70015 & 70016 which were briefly allocated to Stratford 30A, in 1952 and into 1953.

GWR Lamp Irons were applied to the 15 Locos on the WR lines; these were fitted by Crewe in production, and were the same type as those used all over the GWR system. No 70015 Apollo had GWR Lamp Irons, but was loaned to the LMR and used on the GE section before arrival at Old Oak in September 1953.

SR Lamp Irons had to be fabricated to suit the Britannia Class, being fitted onto the lower stays of the smoke deflectors, and these could be seen on Nos 70004, 70009, 70014, 70017, 700023, 70024, 70028, 70029, 70030 & 70034 (see inset left of 70004 heading the 'Golden Arrow').

SR Lamp Irons had to be fabricated to suit the Britannia Class, being fitted onto the lower stays of the smoke deflectors, and these could be seen on Nos 70004, 70009, 70014, 70017, 700023, 70024, 70028, 70029, 70030 & 70034 (see inset left of 70004 heading the 'Golden Arrow'). Long Lamp Irons (right) were only to be seen on two Britannia Class Nos 70004 and 70014 when both locos were allocated to Stewarts Lane MPD for working the prestigious 'Golden Arrow' from London to Dover and Folkestone. This modification was devised to prevent the train lamps from 'blowing out' in the winter months, which might sound absurd, but records show that a signalman on the route had stopped the train on a number of occasions because he was unable to identify which train was coming towards him in the dark. The problem was deemed serious, but the matter was not fully resolved until the Foreman Fitter at Stewarts Lane thought of using the long irons; this type having been used on many Southern Railway locos in previous years.

Long Lamp Irons (right) were only to be seen on two Britannia Class Nos 70004 and 70014 when both locos were allocated to Stewarts Lane MPD for working the prestigious 'Golden Arrow' from London to Dover and Folkestone. This modification was devised to prevent the train lamps from 'blowing out' in the winter months, which might sound absurd, but records show that a signalman on the route had stopped the train on a number of occasions because he was unable to identify which train was coming towards him in the dark. The problem was deemed serious, but the matter was not fully resolved until the Foreman Fitter at Stewarts Lane thought of using the long irons; this type having been used on many Southern Railway locos in previous years.Repositioned Lamp Irons, refers to all of the class from 1963 onwards. This final modification was made in order to safeguard enginemen when working in areas with overhead catenary; the topmost iron was lowered to a position down the smokebox door and the centre iron was realigned also to suit. This configuration can be seen in Jim Carter's photo (below) of 70045 Lord Rowallan heading an 'up' train at Chester...check out Jim Carter's superb 'Footplate Cameraman' Page 32 on the left-hand menu.

(Above-Below) Evidence of the short period working on the Southern Region from May to October 1951 are the SR lamp irons fitted to the lower stay of the smoke deflectors of 70009 Alfred the Great. The loco was allocated to Nine Elms MPD on loan for trials on the Bournemouth Belle. Here 70009 is back on familiar Eastern Region territory at Liverpool Street station. (Below) This ER Morten shot shows 'Britannia' class No 70014 Iron Duke heading the 4.00pm Manchester Central-St Pancras (SO) at Peak Forest on 17th August 1958. Note the height of the express lamp headcode display which is mounted on the SR type elongated lamp irons either side of the buffer beam; also just visible is one of the SR irons on the lower stay of the smoke deflector.

3. SMOKE DEFLECTOR MOD. We will look at four categories in this section: 1. Original type - 16 engines were not changed; 2. LMR type 1 - 25 engines received this modification; 3. LMR type 2 - 5 locos were so

treated, and finally 4. WR type - 9 engines received this design.Original type - those that were basically maintained at Crewe Works, and included Nos. 70004, 70014, 70021, 70031, 70032, 70033, 70042, 70043, 70045, 70046, 70047, 70048, 70049, 70050, 70051 & 70052 (total 16). Of note, that although No 70021 was on the WR for 7 years, she was not changed in any way, and No 70042 was allocated to GE section for almost 5 years, yet it wasn't altered at all. The handrails on the smoke deflectors were sometimes referred to as 'the dangerous handrails' by engine crews in direct reference to the decision made to remove them on safety grounds.

treated, and finally 4. WR type - 9 engines received this design.Original type - those that were basically maintained at Crewe Works, and included Nos. 70004, 70014, 70021, 70031, 70032, 70033, 70042, 70043, 70045, 70046, 70047, 70048, 70049, 70050, 70051 & 70052 (total 16). Of note, that although No 70021 was on the WR for 7 years, she was not changed in any way, and No 70042 was allocated to GE section for almost 5 years, yet it wasn't altered at all. The handrails on the smoke deflectors were sometimes referred to as 'the dangerous handrails' by engine crews in direct reference to the decision made to remove them on safety grounds.LMR type 1 had the handrails removed, being replaced by two handholds with backing cups, the first to be modified was No 70038 (right) which entered Doncaster Works in November 1957, and emerged in December suitably modified. This started off a programme whereby all GE section engines were altered in a relatively short space of time 2 years. Introduced to traffic on 29th January 1953, to Order No E483/228, No 70038 Robin Hood's career followed a familiar pattern for the GE's 'Britannias' with allocations to Stratford (30A), Norwich (32A), March (31B) and then to Immingham (40B), having just been overhauled, before ending its

days at Carlisle (12A) on the LMR from where it was withdrawn in August 1967. 70038's time at 40B Immingham was spent mostly on Kings Cross-Cleethorpes express turns, though it was doubtless called upon to work the Grimsby-London Fish traffic. This photo of 70038, in a typically-grimy state for the time, was taken at Carstairs on the LMR towards the end of its career, and shows the lamp iron has been removed from the top of the smokebox door and repositioned further down to the right; likewise the centre iron on the buffer beam has been realigned to allow a display of one lamp over the other.

days at Carlisle (12A) on the LMR from where it was withdrawn in August 1967. 70038's time at 40B Immingham was spent mostly on Kings Cross-Cleethorpes express turns, though it was doubtless called upon to work the Grimsby-London Fish traffic. This photo of 70038, in a typically-grimy state for the time, was taken at Carstairs on the LMR towards the end of its career, and shows the lamp iron has been removed from the top of the smokebox door and repositioned further down to the right; likewise the centre iron on the buffer beam has been realigned to allow a display of one lamp over the other.(Below) The last of the class to be treated with modified deflectors was No 70044 in July 1960, also at Doncaster. However, it is worth mentioning that 70044 was fitted with Westinghouse Brake Equipment from almost new and was not seen with smoke deflectors until March 1957. The other member of the class fitted with Westinghouse Brake Equipment was 70043 as seen below.

LMR type 2 were very similar to type 1, but without the backing cups, as seen on Nos. 70017, 70020, 70024, 70028 & 70029, these being modified at Swindon Works between late 1957 and early 1959 [see 70017 below].

I have found no evidence of why this type was chosen, and dates show that at the same time that No.70017 was being repaired, No.70025 was modified to WR type.

I have found no evidence of why this type was chosen, and dates show that at the same time that No.70017 was being repaired, No.70025 was modified to WR type.WR section Locomotives were altered at Swindon Works from early in 1957, when No 70023 (left) was modified. This close-up shot by JR Carter of 70023 not only shows the six brass-lined handholds, but also of interest is the lamp iron mounted at the top of the smokebox; this is a GWR type, whereas the lamp iron on the smoke deflector stay is of SR origin and the buffer beam carries a mix of LMR and GE irons (short and long respectively). The first engine allocated to the WR was No 70015 Apollo, which had the smoke deflector modification done 12 months later, having 6 cut-outs in each deflector sheet. The majority of these handholds were brass-lined, which added to the overall look of the WR engines, being usually kept in very clean condition by staff at Cardiff Canton MPD. The nine Locomotives were: 70015, 70016, 70018, 70019, 70022, 70023, 70025, 70026 & 70027. A spruced-up 70022 Tornado can be seen below at Cardiff Canton shed.

(Above-Below) The subject of smoke deflector modifications would fill a whole web page of its own, since a large number of variants appeared following the involvement of 70026 Polar Star in the Milton crash on 20th

November 1955 in which 11 people lost their lives. Also known as the 'Didcot Accident', the enquiry concluded that the driver's view of relevant signals had been obstructed in part by the handrails on the smoke deflectors, although the Crash Investigation Committe also acknowledged other contributing factors. Their findings resulted in Swindon Works devising some modifications to improve the situation, hence many Britannias were fitted with a GW type deflector consisting of six handholds cut into the deflector, many with brass surrounds. Nine engines were modified in this manner, although oddly enough 70026 was not the first to be treated! However, Crewe Works did not modify any engines that went through Major Overhauls, giving the distinct impression that they did not concur with the Crash Committee's findings. Meanwhile Doncaster Loco modified most of the Britannias in due course of shopping, though